JT Series Lube Oil Purifier

- JT Series Lube Oil Purifier is a kind of machine to filter waste lube oil and other kinds of waste oil.

- High efficiency and good effect in filtering waste lubricating oil.

- Dehydrates by 2 kinds of filter elements.

- Coalescing filter will make the free and dissolved water from small molecules to big drop, then separation filter removes the drop by gravity, falling into the water tank.

Share to

Definition of Lube Oil Purifier

JT Series Lubrication Oil Purifier combines the functions of precision filtration and high-efficiency dehydration. It uses advanced “coalescence separation” technology for dehydration, high dehydration efficiency, and strong ability, especially for the separation of a large amount of water in lube oil.

Functions of Lube Oil Purifier

- The JT Series Lube Oil Purifier outperforms the vacuum and centrifugation methods by breaking down all oil-water emulsions in the medium.

- Using a particle filtration system maintains stable medium cleanliness as per system requirements to ensure clean oil.

- The JT series coalescing dehydration lube oil purifier machine is well-equipped with an excellent system set up and offers continuous performance, suitable for online operation.

- The particle filtration system uses high-efficiency filtration material with a large filtration area, effectively filtering very fine particle impurities to achieve highly clean oil.

Features of Lube Oil Purifier

- The pipelines and tank of the purifier can be stainless steel or carbon steel.

- An oil/water interface detector is used to monitor the water level and discharge water automatically.

- The electric system is controlled by PLC (with touch screen), the working conditions of all the parts are displayed clearly, and monitoring, alarming, action control, and safety stops enable the oil filtration machine to run online.

- Germany brand oil pump has good sealing quality, low noise, and long service life.

- Multilayer filtration can remove the impurities through coarse filter, protecting filter, and fine filer. The granularity test is good for achieving NAS6.

- YUNENG also provides turbine oil purifiers, hydraulic oil purifiers, and other oil filters.

Lube Oil Purifier Specification

| Item | Parameter | Unit Model | JT-50 | JT-100 | JT-150 | JT-200 | |

| Technical Parameter | Flow Rate | L/MIN | 50 | 100 | 150 | 200 | |

| Working Pressure | Mpa | ≤0.35 | |||||

| Temperature Range | ℃ | 45-65 | |||||

| Power Supply | (380V~50Hz) 3Phase 4Wires, or as per buyer’s option | ||||||

| Total electric power | KW | 1.5 | 3 | ||||

| Pipe diameter of oil Inlet/Outlet | DN | 25/25 | 40/40 | 50/50 | 50/50 | ||

| Size | Length | CM | 155 | 175 | 190 | 200 | |

| Width | CM | 100 | 110 | 120 | 130 | ||

| Height | CM | 140 | 165 | 155 | 160 | ||

| Weight | Kg | 400 | 450 | 550 | 700 | ||

| Oil Treatment Index | Water Content | ppm | ≤150 | ||||

| Cleanness | NAS | ≤6 | |||||

| Filtering Accuracy | µm | 3 | |||||

The machine size, and weight will change slightly due to different configurations.

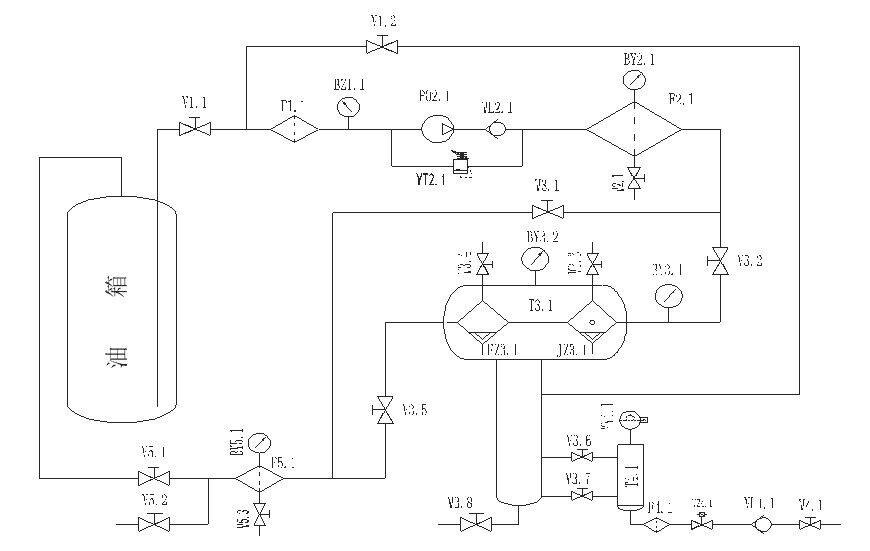

How does Lube Oil Purifier Work?

- Lower surface tension makes liquid flow faster through pores.

- Mixed liquids first go through the coalescing filter in the separator, which has multiple layers with increasing pore sizes.

- Oil moves quickly through the filter due to differing surface tension from water.

- The hydrophilic material of the coalescing filter attracts tiny water droplets, causing them to merge.

- Small droplets combine into larger ones due to kinetic energy and settle away from the oil due to gravity.

- Moving forward, oil passes through the separation filter in the separator, blocking water droplets outside, and allowing only oil through the outlet.

- Two filters, the coalescing and separation filters, serve different functions inside the coalescing separator.

- Oil, in the coalescing separator, goes through four stages—filtration, coalescence, sedimentation, and separation—to remove water and filter out particulate pollutants.

What is the Principle of Lube Oil Purifier?

Particle Filtration System→Coalescence System→Separation System→Drainage System

Why Choose YUNENG’s Lube Oil Purifier?

- The coalescing filter element of the Lube Oil Purifier produced by YUNENG is made of special glass fiber and other synthetic materials, specially formulated for oil dehydration, and has good hydrophilicity. The function of the coalescing filter is to filter particulate pollutants and agglomerate moisture. The innermost high-precision filter material first filters out the particulate pollutants in the oil, and then the outer demulsification coalescing layer coalesces the tiny water droplets in the oil into water droplets.

- The separation filter uses specially treated stainless steel mesh and is hydrophobic. Bigger water droplets fall to the sump due to gravity, while smaller ones mix with oil and reach the separation filter before settling. Oil passing through the separation filter from outside to inside effectively captures small water droplets outside the filter. Only oil is allowed through, preventing water from passing, further separating it.

- This series of Lubrication Oil Purifier has the functions of high-efficiency dehydration, precision filtration, and automatic demulsification. It filters and removes moisture and impurities from the oil to a limited extent.

What is the Main Purpose of Lube Oil Purifier?

This machine is used to purify or filter light oil and turbine oil with a kinematic viscosity of less than 46m㎡/s.

If you have additional knowledge or products you would like to know about, or if you would like to customize a special product for your application, please contact YUNENG.

WHY CHOOSE US

Rich Experience

Leading manufacturer in industrial oil and gas treatment with more than 25 years experiences.

Tailored Design

Specializes in making your systems suit your needs & requirements. Every system is custom engineered & custom designed.

Professional Technical Team

Professional pre-sales, in-sale and after-sales service team to meat customer’s requirement

Reliable Quality, Durable System

Top-quality components and workmanship ensure high performance