Never Underestimate the Importance of Lubricating Oil Purifiers

This article will introduce the function of lubricating oil and the hazards of contaminated lubricating oil and introduce several different types of lubricating oil purifiers.

The Concept and Function of Lubricating Oil

Lubricating oils are used in various types of automobiles and mechanical equipment to reduce friction and protect machinery and processed parts. The main functions are lubrication, rust prevention, cleaning, auxiliary cooling, sealing and buffering, etc.

Lubrication

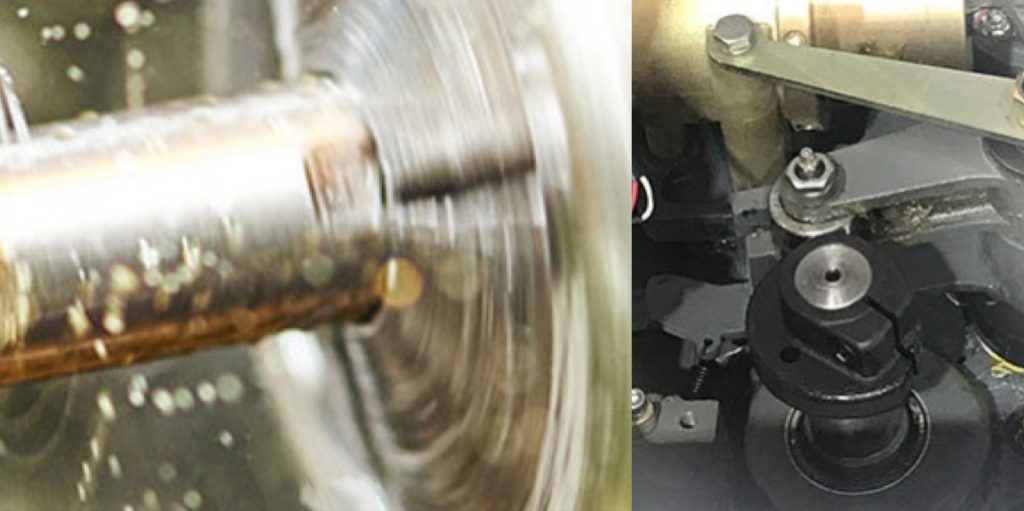

Dry friction occurs when certain friction areas are not properly lubricated while the engine is running. The heat generated by dry friction in a short period of time will melt the metal, causing damage to the parts or even stuck. The clean lubricating oil can form a lubricating oil film on the working surface of the engine’s moving parts. Replacing dry friction of parts with liquid friction can reduce part wear and power consumption.

Cooling Effect

The excess heat in the engine must be expelled from the body. Otherwise, the engine will burn out due to excessive temperature. The lubricating oil circulates through the lubrication system, and all the bearings and moving parts are bathed in the oil flow. The lubricating oil absorbs heat from the surfaces of the cylinder, piston, crankshaft, etc., and then brings it to the oil pan for dissipation.

Cleaning

When the engine is working, the drawn air contains dust, sand, etc., producing solid carbon after combustion. After the lubricating oil is oxidized, a jelly is formed, and the parts are worn to generate metal particles, etc. These contaminants can increase wear on parts and cause the engine to not run properly. Through the circulation and flushing of lubricating oil in the body, the dirt can be brought back to the oil pan from the working surface of the parts so that the friction surface can be cleaned.

Sealing

There is a certain gap between the cylinder and the piston, the piston ring, and the ring groove of the engine. Moreover, these parts have certain geometrical deviations so that there is a gap between the movable surfaces. These gaps can cause poor cylinder sealing, and lubricating oil can fill these gaps and voids to seal and reduce gas leakage.

Shock Absorption

The gap between the crankshaft journal and the bearing is filled with lubricating oil. When the mixture in the cylinder burns and the load on the piston increases suddenly, the lubricating oil in the bearing clearance acts as a buffer. As a result, the engine can work smoothly, and direct metal contact is prevented, reducing wear.

Anti-Corrosion Effect

The oil film formed by the lubricating oil on the surface of the parts can avoid the direct contact between the parts and water and acid gas and prevent corrosion and rust.

Hazards of Water, Gas, and Impurities in Lubricating Oil

1. Reduce the Quality of Lubricating Oil.

The moisture in the lubricating oil will promote the oxidative deterioration of the base oil to produce emulsification, which makes the lubricating oil easy to vaporize and generate air bubbles when the temperature is high. It not only destroys the oil film but also damages the bearing bush, and it is easy to form a steam blockage, which affects the normal circulation of the lubricating oil circuit. And cause additive failure.

2. Reduced Lubricating Capacity.

The deterioration of the base oil and the failure of the additives in the lubricating oil reduce the thickness and stiffness of the oil film, thereby reducing the bearing capacity of the oil film and reducing the lubricating performance of the oil. Oil lubrication, cooling, and flow properties are reduced, accelerating metal surface fatigue.

3. Cause Equipment Wears, Corrosion and Rust.

The water in the lubricating oil and the air act together on the steel parts, and it is easy to have an electrochemical corrosion reaction, which causes the parts to rust.

4. Promote the Formation of Sludge.

Moisture can also react with impurities in lubricating oil, such as iron filings, to form iron soap, which forms sludge with larger particles in the oil, such as colloid, which blocks components.

It is precisely because the above-mentioned lubricating oil contains the hazards of water, gas, and impurities. So we need to filter and purify the lubricating oil.

Different Types of Lubricating Oil Purifiers

JT Series Lube Oil Purifier

JT series coalescing dehydration oil purifier is equipped with coalescing filter elements made of hydrophilic material and dewatering filter elements made of hydrophobic material according to a certain proportion. The free water and emulsified water in the oil are coalesced into larger diameter water droplets after passing through the coalescing filter element. Then a large number of water droplets are separated out through the dewatering filter element. Finally, it settles in the water storage tank under the action of gravity and is automatically drained, thus completing the oil-water separation.

This machine can filter the water and impurities in the oil to a limited extent and is suitable for turbine oil, lubricating oil, and light oil whose kinematic viscosity is less than 46m㎡/s.

ZJC Series Hydraulic Oil Filtration Machine

ZJC series vacuum oil filtration can effectively filter various pollutants in hydraulic oil and other oil products through the special design of vacuum separation system and impurity filter system. This function can effectively solve the problems of water ingress, emulsification, and particle pollution of oil products.

This machine is mainly suitable for hydraulic oil, turbine oil, mechanical oil, compressor oil, refrigerator oil, and other industrial oils whose kinematic viscosity is less than 320m㎡/s.

DYJC Series Turbine Oil Purifier

The DYJC turbine oil purifier can use a vacuum separation system alone for filtration or only use coalescing dehydration system for online filtration. Of course, it can also use vacuum separation and coalescing dehydration system for filtration at the same time.

This machine is mainly suitable for oil products with high water content and serious emulsification. And can carry out deep dehydration to achieve a good oil quality index.

Conclusion

In addition to a series of lubricating oil purifiers, YUNENG also provides transformer oil purifiers, dry air generators, transformer vacuum pump, sf6 gas recovery etc. We have been committed to the filtration and purification of oil products. If you have related needs, we look forward to serving you.