Transformer Evacuation Systems: A New Way to Revolutionize Transformer Maintenance

Ensuring transformers operate reliably and efficiently is crucial for uninterrupted electricity supply, as they play a vital role in voltage transformation and power distribution within the electrical grid. Regular maintenance, including critical tasks like transformer oil replacement, has traditionally involved draining old oil, introducing fresh oil, and servicing internal components when necessary. However, recent technological advances have ushered in Transformer Evacuation Systems, revolutionizing transformer maintenance. This article delves into their transformative impact.

The Need for Transformer Maintenance

Transformer maintenance is a fundamental necessity in the realm of electrical power distribution. Transformers serve as the backbone of electricity transmission, converting voltage levels to enable efficient energy flow across the grid. Their uninterrupted operation is essential for a reliable power supply to homes, businesses, and industries.

Over time, transformers are subjected to various stressors, such as electrical and thermal loading, which can lead to wear and tear. Regular maintenance is vital to address these issues, ensuring optimal performance, longevity, and safety. Neglecting maintenance can result in costly breakdowns, prolonged outages, and even environmental hazards in the case of oil leaks or gas emissions. Therefore, proactive and systematic transformer maintenance is a cornerstone of grid reliability and sustainability.

The Traditional Way for Transformer Maintenance

Traditionally, maintaining transformers was a laborious task, involving draining insulating oil, purging tanks with nitrogen, and manually vacuuming oil and moisture. This approach was not only time-consuming but also laden with risks, as exposure to electrical currents and imprecise moisture removal jeopardized both personnel safety and transformer longevity. The cumbersome nature of these processes led to increased labor costs and inefficiencies, requiring skilled workers to invest substantial time and effort.

Moreover, the imprecision in moisture removal during manual vacuuming could compromise the transformer’s insulation integrity, impacting its overall performance. Additionally, environmental concerns arose due to the disposal of insulating oil and by-products.

However, with the advent of modern technology, exemplified by YUNENG’s transformer evacuation systems, the landscape of transformer maintenance has undergone a transformative shift. Automated processes, advanced vacuum technology, and precise control mechanisms have replaced traditional methods, mitigating risks, enhancing efficiency, and prolonging the lifespan of transformers. This evolution marks a significant advancement in power equipment maintenance, ensuring a safer, more efficient, and environmentally conscious approach to transformer upkeep.

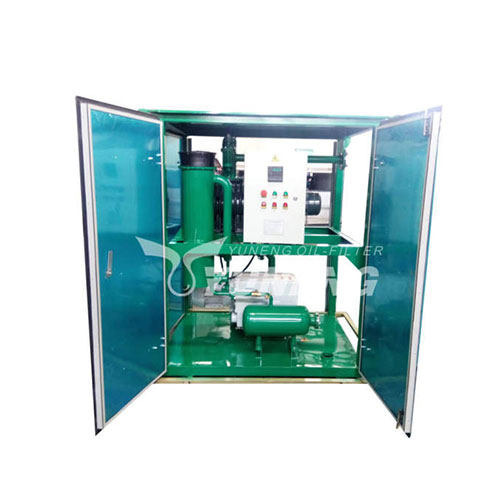

A New Solution for Transformer Maintenance: YUNENG Transformer Evacuation Systems

YUNENG offers a range of highly efficient transformer Evacuation Vacuum Pumps designed for quick starting, high pumping rates, stable performance, and easy handling. These systems are equipped with advanced technology to ensure optimal vacuum conditions in transformer units. The combination of a roots pump as the main pump and a spinning vacuum pump as a pre-stage pump enhances the evacuation process, making it swift and reliable.

Key Features of Yuneng Transformer Evacuation Systems

- Quick Starting

The transformer evacuation systems from YUNENG are engineered for rapid startup, ensuring minimal downtime during the evacuation process. This quick starting capability enhances overall operational efficiency.

- High Pumping Rate

With a roots pump as the main pump and a spinning vacuum pump as a pre-stage pump, these systems achieve a high pumping rate. This feature accelerates the evacuation process, facilitating faster and more effective removal of air and moisture from the transformer.

- Stable Performance

YUNENG’s transformer evacuation systems are designed to deliver stable performance throughout the evacuation process. The combination of reliable components and advanced technology ensures consistent and efficient operation.

- Easy Handling

User-friendly design and intuitive controls make these systems easy to handle. The inclusion of French Schneider Electric as a control element enhances the ease of operation, providing a seamless experience for users.

- Vacuum Meter Control

A vacuum meter is integrated into the system to measure and control the vacuum level within the pumped container. This precision control ensures that the desired vacuum conditions are achieved and maintained throughout the evacuation process.

- Automatic Operation

The unit features full-automatic and non-presence operation, allowing for hands-free operation. Lamps indicating the operational status provide a visual cue, making it easy to monitor the system’s condition.

- Humanization Design

The system is designed with a focus on humanization, ensuring user comfort and convenience. Low noise levels contribute to a more comfortable working environment, while energy-efficient operation makes the system economical to use.

Conclusion

Transformer Evacuation Systems have modernized transformer maintenance, making it faster, safer, and eco-friendly. As the demand for reliable power grows, these systems are now essential for utilities worldwide. By reducing downtime, improving efficiency, and enhancing safety, they ensure transformers continue to play a crucial role in grid stability. The future of transformer maintenance is promising thanks to these innovations.