Transformer Oil Regeneration Machine: The Key to Cost Savings for Enterprises

For companies utilizing transformers, managing and maintaining transformer oil is simply an operational expense. On the other hand, optimizing operations and reducing costs has always been the focus of any company. With the proper methodology, equipment reliability, service life, and cost can be minimized. This is precisely where transformer oil regeneration machines come in.

Table of Contents

Defining the Necessity of Transformer Oil Management

Electrical transformers need transformer oil for its proper esturgeon. It acts as an insulator, dissipates heat, and prevents oxidation of the transformer’s internal components. Having said that, at some point, oil will lose its quality due to heat, moisture, andimai other contaminants. This decline alongside it will reduce performance, risk of failures will be increased, and platics will be higher, and more expensive maintenance will also be Idealquire.

In the past, businesses have had two choices with transformer oil that has either become contaminated or is no longer performing: dispose of it and replace with new oil, or attempt to purify it through several different methods. Getting rid of the old oil incurs waste management costs alongside the purchasing new oil which can be quite expensive. Purification methods that are more traditional can be slow, expensive, and often ineffective in restoring the oil back to its original quality.

How Transformer Oil Regeneration Machine Work

Transformer oil regeneration machines offer a more efficient and cost-effective solution. This kind of machine uses technology to clean the oil of different contaminants and breakdown products while restoring its characteristics so that it can be used effectively and efficiently for the longest possible time. This is how oil regeneration machines work in a nutshell:

- Degassing and Dehydration: Applying vacuum separation methods in removing moisture, gases, and other volatile contaminants to oils helps in preventing the ransformers from sludge and many other harmful byproducts associated with oil hyraulic fluids.

- Filtration: At times tanks have amalgamated sediments, dusts, and even suspended solids from oils which has to be monitored on frequent basis so as not to cause damaging and upsetting effects on the engines. Filtration operates at high precision which is designed to eliminate small and cut dirt as well as other struvite clarifier liquids.

- Adsorption and Regeneration: It is possible for some machines to apply adsorption filters able to remove oxidized material contaminants. Such filters which possess the ability to be exercised and cleansed to a certain extent can be made use of over and over and do not have to undergo sacrifical processes.

Cost Saving Transformer Oil Regeneration Machines

Lower Costs for Buying Oil

One of the advantages that saves the right money directly is reduced needing to purchase new transformer oil. Rather than throwing away the contaminated oil, it can now be saved back to a near ideal condition. This can help save a ton, especially for companies that have numerous transformers, or in businesses where oil degradation happens at an increased rate.

Improved The Lifespan of The Equipment

These machines help in maintaining the quality of the transformer oil. Damaging contaminants and oxidation will be mitigated for the transformer’s internal components. This can significantly boost the lifespan of the transformer, reducing expensive repairs or replacements that occur frequently. In the end this can greatly reduce maintenance as well as capital expenses.

Reduced Energy Consumption

An increase in energy usage is caused by poorly maintained oil which reduces transformer efficiency. Restoring the oil will help improve the transformer’s efficiency, which in turn results in lower energy bills, reduced operational costs and overall lower energy consumption.

Minimized Downtime

If a transformer fails due to oil contamination, a business may face costly unplanned downtime. With proper maintenance, these machines can mitigate failures and maintain product quality while preventing needless downtime. This consistent operation supports streamlined operations and maximized productivity for any business.

Savings in Waste Management and Environmental Costs

The environmental regulations surrounding the disposal of used transformer oil increase its cost considerably. At the same time, businesses that purify the oil on-site reduce the amount of waste oil that requires disposal, thereby lowering waste management costs while simultaneously minimizing their environmental footprint.

The YUNENG Advantage: Specialized Regeneration Solutions for Transformer Oil

YUNENG is an industry leader in manufacturing oil and gas treatment systems. Their transformer oil regeneration machines are specifically tailored to the different needs of businesses. YUNENG has been serving the industry for 30 years and has built a reputation for providing reliable, high-quality, and affordable solutions.

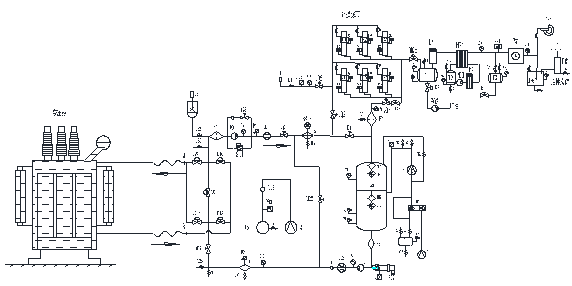

ZJA2BY–BO Transformer Oil Reclamation Machine

Clients love YUNENG for their innovation, and the ZJA2 BY-BO model is a great example. This ZJA2 BY-BO machine has a high flow rate of 2000L/h and can reduce the water content in the oil to less than 5 ppm. The machine also reduces gas content to less than 0.5% volume ratio. It achieves a micronic filter precision of 1μm and a breakdown voltage of greater than or equal to 75 kV with the spherical electrodes. This machine comes with rechargeable regeneration filters which helps restore the oil’s performance, extending its service life and saving businesses money on replacement oil and maintenance costs.

YZS Series Transformer Oil Regeneration Machine

For businesses aiming to enhance their processes in transformer oil maintenance, the YZS series presents yet another excellent choice. This machine boasts vacuum separation, oil atomization, and oil regeneration for the servicing of oil to remove moisture, impurities, and oxidized materials. In addition, the YZS series has adsorption filters that are capable of regeneration and reuse, which reduces operational costs.

The ZJA2BY-BO and YZS series machines reflect the safety, efficiency, and environmental considerations of the modern industry. Operating under full-closed conditions ensure minimal environmental impact as well as safety to the operator. In addition, other manufacturers do not enjoy these advantages because of YUNENG’s personalized design strategy which enables customers to adapt the machines to their needs.

Making the Investment: A Smart Business Decision

The initial cost of a transformer oil regeneration machine may appear significant, but the long-term advantages and savings easily surpass the initial investment. The machine pays for itself by cutting down on oil replacement costs, improving the life of other equipment, decreasing energy use, reducing service interruptions, and meeting eco-friendly regulations.

For businesses looking to improve cost management while enhancing the operational efficiency of their enterprise, the purchase of a YUNENG transformer oil regeneration machine can prove to be a strategically sound investment. YUNENG provides integrated solutions for the management of transformer oil which helps businesses realize sustainable savings. With advanced technology and reliable performance, their machines offer customizable solutions which help optimize the processes.

Conclusion

In conclusion, cost-effective strategies along with improved equipment reliability and outage management through enhanced transformer oil management provided by YUNENG gives enterprises the capability to reduce their environmental impact. The introduction of YUNENG’s advanced regenerative solutions allows enterprises to be more proactive in cost and operational performance while embracing the need for dynamic change in today’s competitive market.