6000LPH High Vacuum Transformer Oil Purifier

- The 6000LPH high vacuum transformer oil purifier has excellent performance in both design and cost.

- The process and perfoemance of this series machine from YUNENG are the best in China.

- The machine has the advantages of a high working vacuum, fast oil filtration speed, and oil quality protection.

- This series includes two types: fixed close type and mobile trailer mounted type.

- The machine is suitable for oil treatment and transformer vacuum oiling during big transformer installation and maintenance.

Share to

What is a High Vacuum Transformer Oil Purifier?

The YUNENG high-vacuum transformer oil filtration machine utilizes a double-stage process to efficiently remove moisture, dissolved gasses, and particulate contaminants from transformer oil. This results in improved dielectric strength, extended transformer life, and enhanced operational efficiency. It can purify and treat unqualified electrical insulating oil in industrial and mining enterprises such as power plants, power stations, power companies, metallurgy, petrochemicals, railways, etc.

YUNENG, a trusted name in transformer oil purifier equipment, offers a diverse range of high-quality, competitively priced systems. Whether you have standard or unique needs, we have the perfect solution for you, with options for customization to match any requirement.

According to Flow Rate, in addition to 6000LPH, YUNENG can also supply 1800LPH, 3000LPH, 9000LPH, 12000LPH, 18000LPH, and other models.

Depending on the environment of use, you can choose closed, open, or trailer-mounted transformer oil purification machines.

- Closed: This transformer oil filtration machine is suitable for outdoor use and prevents climbing.

- Open: This oil purifier is suitable for indoor use without metal doors or trailers.

- Trailer: The trailer-mounted oil purifier is suitable for situations where the machine needs to be moved from one site to another.

High Vacuum Transformer Oil Purifier Specification

| Item | Parameter | Type Unit | ZJA1.8KY | ZJA3KY | ZJA6KY | ZJA9KY | ZJA12KY | ZJA18KY | |

| Technical Parameter | Flow Rate | L/H | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 | |

| Working Vacuity | Pa | ≤80 | |||||||

| Working Pressure | Mpa | ≤0.35 | |||||||

| Temperature Range | oC | 45-65 | |||||||

| Power Supply | 50Hz 380V 3-Phase 4-Wire (or as requested) | ||||||||

| Total Power | KW | 16 | 36 | 70 | 100 | 150 | 200 | ||

| Inlet/Outlet Diameter | DN | 20/20 | 25/25 | 32/32 | 40/40 | 50/50 | 65/65 | ||

| Size | Length | Cm | 160 | 180 | 220 | 250 | 280 | 345 | |

| Width | Cm | 125 | 145 | 160 | 195 | 215 | 260 | ||

| Height | Cm | 200 | 220 | 245 | 270 | 300 | 300 | ||

| Weight | Kg | 650 | 900 | 1200 | 1600 | 2200 | 3000 | ||

The machine size and weight will change slightly due to different configurations.

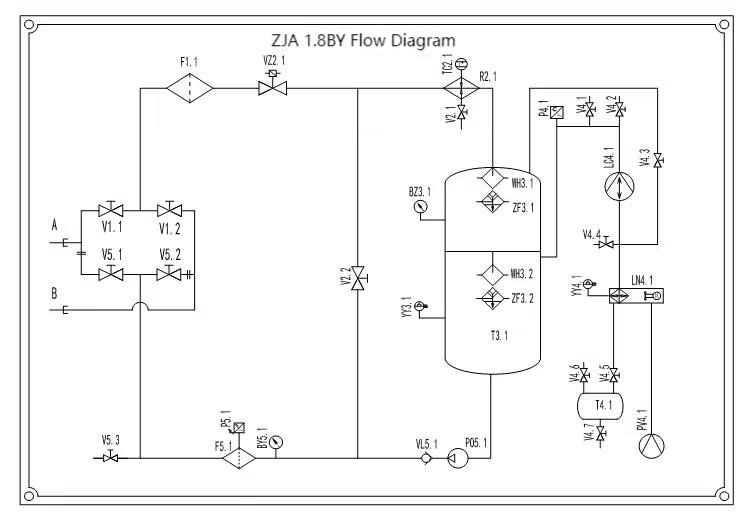

What is the High Vacuum Transformer Oil Purifier Working Principle?

- The 6000LPH high vacuum transformer oil purifier works by passing oil through the machine to remove impurities.

- The machine uses a special vacuum separator that uses the principle of cavitation.

- Cavitation expands the contact area of the oil in the vacuum separator hundreds of times.

- The cavitation system continuously increases the surface area of oil evaporation and constantly updates the evaporation interface.

- This maximizes the oil travel in the vacuum system and the static water volatilization area.

- As a result, the water in the oil can be quickly evaporated under conditions of low heat, high vacuum, large surface, and high pumping speed.

- The evaporated water is then discharged from the vacuum system.

What are the Advantages of the High Vacuum Transformer Oil Purifier?

The advantages of vacuum transformer oil purifiers produced by YUNENG are as follows:

- The transformer oil purification system is a purification technology that integrates low-temperature physical adsorption (removal of dielectric loss, decolorization, and deodorization) and online regeneration of adsorption filters. It has functions such as high-speed purification and oil quality protection. hydrocarbons.

- The oil purifier is specially designed for the purification of electrical insulating oil in oil-filled electrical equipment, especially for the purification of UHV, EHV transformer oil, or other insulating oils.

- This oil purifier can be used to degas, dehydrate, filter, and restore the dielectric strength of insulating oils. Through dehydration, degassing, filtration, and other processes, dissolved gas, moisture, solid particles, and pollutants can be completely removed.

- The oil purifier is a very efficient, durable, and user-friendly high vacuum oil purification device on the market today. Purpose-designed design features maximize the pumping rate of our systems, and state-of-the-art components and workmanship ensure years of maintenance-free operation and performance.

Flow Chart of High Vacuum Transformer Oil Purifier

How is the High Vacuum Transformer Oil Purifier Operating?

The following describes the operation of transformer oil purification plants:

1. Initial Setup and Pre-Start Checks

- Vacuum Level: Set the desired vacuum level on the electric contact vacuum gauge within the range of -0.07 MPa to -0.09 MPa. This range may vary slightly depending on the specific purifier model and altitude.

- Temperature Control: Set the temperature controller to a suitable temperature range based on the oil type and altitude. Generally, a temperature range of 45°C to 65°C is recommended.

- Valve and Equipment Checks: Ensure all valves are closed and the vacuum pump is primed and ready for operation. Verify the proper functioning of the oil level gauge, solenoid valves, and other control systems.

2. Vacuum Pump Activation and Monitoring

- Open the intake valve on the vacuum pump and start the pump.

- Closely monitor the vacuum gauge to ensure the vacuum level steadily increases and reaches the pre-set value within the specified timeframe.

3. Electrical Activation and Oil Processing Initiation

Once the desired vacuum level is achieved, activate the electrical contacts. This will automatically trigger the following actions:

- Oil Inlet Solenoid Valve: Opens, allowing oil to flow into the vacuum tank.

- Heater: Activates when the temperature controller reaches the setpoint and the oil inlet solenoid valve is open, ensuring proper oil heating during processing.

4. Automatic Oil Level Control and Circulation

As oil enters the vacuum tank, the infrared oil level controller monitors the level.

- Lower Limit: When the oil level reaches the lower limit, the controller automatically opens the oil outlet solenoid valve and starts the oil pump. This initiates oil circulation through the purification process.

- Upper Limit: If the oil level exceeds the upper limit, the controller automatically closes the oil inlet solenoid valve, stopping oil inflow and preventing overflow.

- Low Level Protection: If the oil level falls below the lower limit, the controller automatically stops the oil pump, protecting the purifier from dry pump operation.

5. Oil Sampling and Analysis

- After the purifier operates stably for a sufficient period and the oil has been circulated through the system several times, representative oil samples can be collected from the designated sampling port.

- These samples should be analyzed for relevant parameters like dielectric strength, moisture content, and particulate contamination to assess the oil’s condition and purification effectiveness.

Oil Data After Filtration

| Item | Type Unit | Oil Treatment Index |

| Breakdown Voltage | KV | ≥70 (Spherical electrodes) |

| Water Content | ppm | ≤5 |

| Gas Content | % | ≤0.3 |

| Filtering Accuracy | μm | 1 |

What is the Difference Between Single-stage Transformer Oil Purifier and Double Stage Transformer Oil Purifier?

The single-stage transformer oil purification plant is applicable to the treatment of insulating oil of small transformers and the purification of transformer oil, transformer insulating oil, circuit breaker oil, etc. It is applicable to transformers below 110KV. The equipment is simple to operate and can quickly and efficiently filter water, gas, impurities, etc. in oil products. It is mainly used in power plants, substations, power industry, etc.

The double-stage transformer oil purification system is applicable to the oil purification treatment and vacuum hot oil circulation drying during the installation and maintenance of various large transformer equipment. Especially suitable for transformers above 110K. The function of the two-stage transformer oil purifier is more perfect than that of the single-stage vacuum oil filter. The effect of removing mechanical impurities, gases, moisture, water-soluble acids, and alkalis is faster and more thorough, and the ultimate insulation strength and flash point of oil products are improved more.

What is the Difference Between a Vacuum Oil Purifier and a Centrifugal Oil Purifier?

The dehydration speed of a centrifugal oil purifier is very fast, but the filtering accuracy is not as high as that of a vacuum oil purifier. The micro water cannot be filtered, the emulsification cannot be broken, the gas cannot be removed, and the acid value cannot be reduced. It is not suitable for industrial oils with high requirements on cleanliness, water content, and gas content.

The centrifugal oil purifier needs to clean the system frequently. The system installation workload is large, the installation requirements are high, and the equipment cost is high. Therefore, many power plants and steel plants have stopped using centrifugal oil purifiers.

The vacuum oil purifier is very suitable for filtering various industrial oils with high water content requirements. Suitable for precision filtration, at a moderate price. Both new oil and oil deteriorated after use is suitable for vacuum oil filters.

WHY CHOOSE US

Rich Experience

Leading manufacturer in industrial oil and gas treatment with more than 25 years experiences.

Tailored Design

Specializes in making your systems suit your needs & requirements. Every system is custom engineered & custom designed.

Professional Technical Team

Professional pre-sales, in-sale and after-sales service team to meat customer’s requirement

Reliable Quality, Durable System

Top-quality components and workmanship ensure high performance