Transformer Vacuum Pump Oil Level is Too Low? Don’t Panic! See the Solution Here

In the daily operation and maintenance of the power system, the normal operation of the transformer is crucial, and the low oil level of the transformer vacuum pump, an essential vacuum pump machine, is a problem that cannot be ignored.

Table of Contents

How Low Oil Level Harms a Transformer Vacuum Pump

Low oil in the transformer vacuum pump hurts the machine in several ways, mainly by messing with lubrication, cooling, sealing, vacuum strength and overall work rate.

Impact on lubrication

Insufficient oil supply reduces lubrication between moving parts, increasing friction and accelerating wear. The oil film may thin or rupture, causing metal-to-metal contact, temperature spikes, and loss of precision. Unaddressed, this leads to cumulative damage, increased repair costs, unplanned downtime, and reduced pump lifespan.

Effect on Cooling

When a vacuum pump runs with too little oil, the cooling action drops fast because there isnt enough lubricant to carry away heat. As the pump keeps working, trapped heat keeps building up, pushing the temperature even higher. Hot oil thins out, loses its ability to resist oxidation, and can no longer shield moving parts or cool the system, setting off a nasty loop. Meanwhile, seals may crack or warp, motors and other electrical bits can overheat, insulation wears out, short circuits strike, and the whole unit may fail or create a serious safety risk.

Impact on Sealing

Transformer vacuum pumps rely on tight seals to operate smoothly, and clean oil acts as a secondary gasket by filling very small spaces between parts. When the oil level drops, the film at the seal thins or vanishes, allowing air, dust, and other particles to push inside the pump. These intruders ruin the internal clean room and weaken the vacuum level. Poor sealing then stops the pump from reaching its target vacuum, lowers overall efficiency, and cuts the transformers drying power, leaving the unit unprotected during installation or service.

Impact on Vacuum Maintenance and Work Efficiency

When the oil level in a vacuum pump runs low, the vacuum rises erratically or drops altogether. That weak vacuum fails to pull air and moisture out of the transformer, leaving bubbles and damp spots trapped inside. As a result, insulation may degrade and the transformers long-term reliability shrinks. Because the pump now struggles to reach target pressure, the work cycle drags on. Operators waste time, power, and money, so overall process efficiency slides.

Why Does the Transformer Vacuum Pump Oil Level Appear Too Low

Low oil in a transformer vacuum pump shows up during routine use, yet its cause can puzzle even seasoned crews. A few common issues keep popping up.

Transformer leakage

Oil level drops rapidly when oil leaks out of the transformer itself. Old seals may fail, or internal parts such as gaskets, diaphragms, and bellows can crack or tear. When that happens, insulating oil escapes into areas it should not reach, leaving behind a telltale drop in the sight glass. Replacing worn parts and checking seals promptly keeps the system full and the vacuum strong.

Breather blockage

When the breather in a transformers vacuum-pump system gets clogged, the oil-level gauge may show a high reading even though the oil is really low. The same thing happens if gas builds up in the conservator chamber, because trapped air pushes the oil higher and tricks the operator into thinking there is plenty of fluid.

Oil level indicator failure

For monitoring to work, the oil-level sight glass or gauge must be in good shape. A stuck float, cracked glass, or broken sensor means the tool either freezes at one spot or never moves, leading the user to believe the tank is dangerously low when it actually might be fine.

Should the vacuum-pump oil level seem too low, an operator can review these points, clear blockages or repair the gauge, and keep the pump-and, by extension, the whole transformer-running safely and smoothly.

Effective Solutions

Inspect and Address Leaks

- Prepare Inspection Tools: Get a flashlight, oil bucket, cloth, and sealant ready to check for leaks and fix them promptly.

- Conduct a Thorough Inspection: Check the transformer, especially the oil reservoir’s diaphragm, bladder, bellows, and seals like flange joints and valves, for oil traces or damage.

- Identify Leak Points: If oil is found, determine the exact leak location and severity. For tiny leaks, apply soapy water to suspect areas and look for bubbles.

- Fix Leaks: Replace damaged seals, gaskets, or parts. Apply sealant evenly and install parts properly to ensure good sealing.

- Check Repair Effectiveness: After repairs, recheck the area. Run the transformer briefly to monitor oil levels and ensure no leaks remain.

Unclog the Breather

- Prepare Cleaning Tools: Have tools like screwdrivers, wrenches, cleaning brushes, and a cloth ready for breather disassembly and cleaning.

- Remove the Breather: Disassemble the breather carefully to avoid damage.

- Check for Blockages: Inspect the breather’s interior for dust, debris, or damaged filters.

- Clean and Unclog: Clean minor blockages with a brush and cloth. Replace heavily clogged filters or components.

- Reinstall the Breather: Reinstall the breather securely. Ensure it’s breathable by checking for airflow during operation.

- Regular Maintenance: Schedule regular breather cleaning and inspections to maintain breathability.

Oil Injection and Air Release for the Oil Reservoir

- Prepare Tools and Materials: Have qualified transformer oil, oil injection equipment, and tools ready.

- Ensure Safe Operating Conditions: Confirm the transformer is off with appropriate safety measures in place before oil injection and air release.

- Connect Oil Injection Equipment: Attach it to the oil reservoir’s injection port securely.

- Begin Oil Injection and Air Release: Open the injection valve and slowly add oil while monitoring the oil level gauge. Release trapped air via the reservoir’s vent valve or hole until oil – free air exits.

- Control Injection Speed and Oil Level: Inject oil slowly to prevent equipment damage from bubbles or shock. Adjust the oil level to the normal range (usually 1/2 – 2/3 on the gauge), following equipment requirements.

- Check Effectiveness: After completion, close valves and check for stable oil levels and proper seals.

Inspect or Replace the Oil Level Indicator

- Prepare Tools and Replacement Parts: Get a multimeter, screwdriver, wrench, and a new oil level indicator.

- Inspect the Indicator’s Appearance: Check for obvious damage like a broken casing or missing parts. Replace it immediately if damaged.

- Test the Indicator: Use a multimeter to test its electrical and functional performance. Compare its reading with the actual oil level.

- Disassemble and Repair: If faulty, disassemble and repair or replace the indicator. Reinstall it according to the manual, ensuring a secure and sealed fit.

- Recalibrate: Recalibrate the indicator by adjusting parameters or its position to match the actual oil level.

- Monitor Operation: After restarting the transformer, monitor the indicator to ensure accuracy and normal operation.

Timely supplement oil

- Prepare Tools and Materials: Have qualified transformer oil, a clean oil drum and hose, wrench, and filtering equipment ready.

- Ensure Safe Replenishment: Confirm the transformer is off with appropriate safety measures. Use oil that matches the original type and quality.

- Connect Oil Replenishment Equipment: Attach it securely to the transformer’s replenishment port.

- Begin Replenishing Oil: Open the valve and slowly add oil while monitoring the oil level gauge to prevent overfilling or underfilling.

- Control Replenishment Volume: Adjust the oil level to the normal range based on the gauge and equipment requirements.

Check Replenishment Effectiveness: After finishing, close the valve and check for leaks. Monitor the transformer for normal operation and stable oil levels.

Conclusion

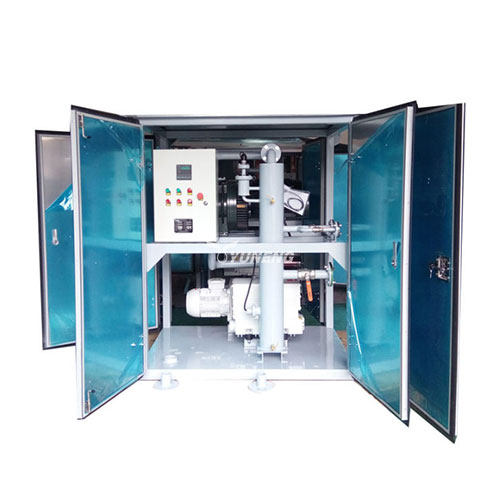

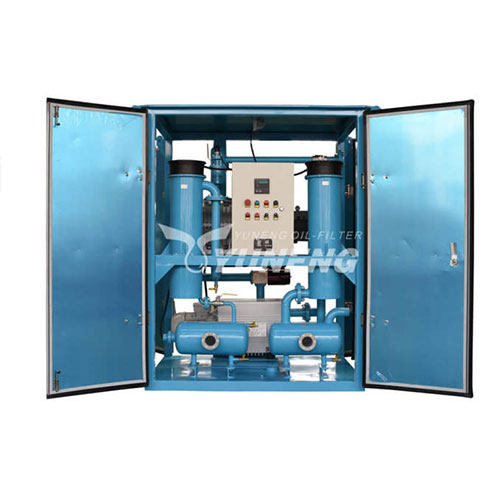

For efficient vacuum pumping and drying solutions, YUNENG offers a range of transformer vacuum pumping systems. Their ZJ Series Vacuum Pump Unit and Double Stage Vacuum Pumping for Transformer are designed to handle vacuum pumping and drying processes effectively.

By following these guidelines and utilizing the right equipment, you can ensure the normal operation of the transformer vacuum pump and maintain the safe and stable operation of the transformer.