3 Methods to Test the Effect of A Transformer Oil Dehydration Machine

Table of Contents

In the power industry, the use of transformer oil dehydration machines is directly related to transformer safety and lifespan. However, relying solely on the equipment itself is insufficient to guarantee results; users must employ scientific testing methods to evaluate its effectiveness. This article will introduce three widely recognized methods: moisture meter, Karl Fischer (KF) method, and ppm moisture determination, to help you more accurately understand the actual effectiveness of transformer oil dehydration.

Why Is It Necessary to Test the Effect of Transformer Oil Dehydration Machine

Although transformer oil dehydration equipment nominally removes moisture from the oil, actual operation may be affected by factors such as equipment sealing, temperature, oil circulation rate, and initial moisture content, resulting in suboptimal dehydration results. Residual moisture in the oil can weaken its insulation properties, cause partial discharge, and accelerate aging.

International standards and industry guidelines typically use ppm (water concentration) as an evaluation metric, setting recommended upper limits for transformer oil moisture content. IEEE Guide C57.106 (“Guide to Acceptance and Maintenance of Insulating Oils”) lists moisture content as a key indicator. IEC standard IEC 60814 (“Determination of Water in Insulating Liquids”) recommends the automated coulometric method (KF). Furthermore, numerous research reviews indicate that the Karl Fischer method offers industry-leading sensitivity and accuracy for low-ppm moisture detection.

Therefore, it is essential to rely on standardized testing methods to evaluate the actual performance of transformer dehydrators in order to better assess the quality of the equipment.

Method 1: Moisture Analyzer Testing

A moisture detector is a portable testing tool commonly used for on-site moisture measurement of transformer oil. Based on principles such as capacitance, conductivity, or infrared spectroscopy, it provides intuitive results quickly. Due to its speed and ease of use, it is often used by power maintenance personnel as a rapid on-site test method to assess the effectiveness of transformer oil dehydration machines.

While moisture detectors may be slightly less sensitive than laboratory testing methods, their greatest advantage is that they provide immediate results upon completion of dehydration of transformer oil. This is particularly critical for power systems that require rapid equipment restoration.

Testing Process

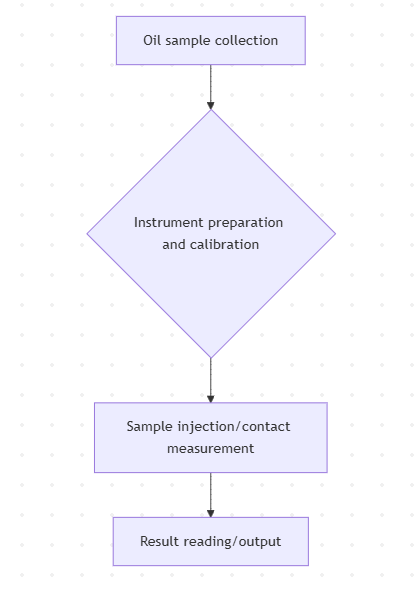

First, after the transformer oil dehydrator completes its operation, collect a representative oil sample from the equipment’s sampling valve. To avoid secondary contamination, use a clean, dry sampling container and keep it sealed.

Next, use a portable moisture detector and inject the oil sample into the detector’s sample cell. The instrument analyzes the oil’s moisture content using capacitance or infrared spectroscopy. Some advanced instruments also support temperature compensation to minimize the impact of environmental conditions on test results.

Finally, analyze the displayed results, typically in units of ppm (parts per million) or mg/kg. Transformer maintenance engineers compare the analysis results with relevant industry standards, such as reference values specified in IEEE C57.106, to reach a conclusion, completing the testing process.

Special Considerations

To ensure the accuracy and validity of test results, avoid secondary contamination of the oil sample by air humidity during the sampling and testing process.

In addition, portable testers require regular calibration according to the manufacturer’s instructions to ensure reliable data.

Finally, excessively high or low oil sample temperatures may affect test results, so the oil sample should be kept at room temperature as much as possible before testing.

Application Value and Scenarios

The advantages of a moisture detector lie in its speed, portability, and real-time performance. It is suitable for three scenarios:

- Quick acceptance testing after dehydration operations;

- Patrol and emergency testing during on-site operation;

- Comparison with laboratory test results to provide a preliminary assessment of oil quality compliance.

Although its accuracy is slightly lower than that of the Karl Fischer method, a moisture detector provides immediate and effective reference data for most O&M needs, making it an indispensable tool for power companies and maintenance teams.

In summary, as a rapid on-site testing method, moisture detectors offer a highly effective method for verifying dehydration effectiveness in power systems, thanks to their ease of operation and real-time feedback. Their portability and speed make them a crucial first step in verifying the effectiveness of transformer oil dehydration machines, helping engineers quickly assess the oil’s water content and providing a reference for further laboratory testing.

Method 2: Karl Fischer (KF) Titration

The Karl Fischer (KF) titration method is widely considered the “gold standard” for testing transformer oil dehydration machine effectiveness. Its core advantages lie in its high precision and sensitivity, enabling accurate determination of moisture content down to the ppm level, making it widely used in both laboratories and industry. The KF method uses a chemical titration reaction to react the water in the sample with iodine, sulfur dioxide, and alcohol reagents, consuming the quantitative reagents and ultimately calculating the water content in the oil. Compared to portable field instruments, the KF method offers greater accuracy and is an authoritative method for verifying the actual performance of dehydrators and assessing oil quality.

Testing Procedure (Coulometric Titration Example)

First, pre-treat a certain volume or mass of dehydrated transformer oil sample (typically 0.1–1 mL). Mix gently to avoid air bubbles or impurities. If the sample is viscous, gently heat it in a heating chamber to reduce the viscosity.

Next, prepare the instrument. Add appropriate reagents (cathode and anodic solutions) to the KF titration cell and perform a “dry conditioning” or drift test to ensure a stable background moisture content. If the drift value is excessive, replace the reagents or clean the cell.

Next, introduce the oil sample into the titration cell using a gas-tight syringe or introduce water vapor from the oil sample into the titration cell using evaporation-adsorption infusion to ensure high-precision measurements.

Then, start the titrator while stirring. The instrument measures the energy consumed by coulometric method or calculates the iodine solution consumption by volumetric method. The final moisture content of the oil sample is expressed in ppm or µg/g.

Finally, calculate the moisture content using the formula:

Water (ppm)=(Titrant consumption – Drift correction) / Sample mass (g) ×106

To be on the safe side, performing blank tests and replicate measurements is recommended to improve precision.

Precision and Advantages

Karl Fischer (KF) testing can measure moisture levels as low as 1 ppm or less. Under standard operating conditions, repeated measurement errors are minimal. Industry standards such as IEC 60814 and ASTM D1533 recommend the KF method for moisture determination.

Special Considerations

Most importantly, the sample collection and injection process must be strictly controlled to avoid air moisture contamination. Secondly, the titration cell drift background must be stable and low. Finally, high-viscosity oils or oils containing additives may interfere with the measurement and require pretreatment measures (heating evaporation, solvent dilution, etc.).

Application Value and Scenarios

KF titration is indispensable for evaluating the performance of transformer oil dehydrators:

- Laboratory verification of the actual dehydration capability;

- Providing precise data for power system maintenance and oil quality upgrades;

- Particularly important for low-water oils (≤10 ppm) and long-term oil monitoring.

Its accuracy and authority make it the preferred method for oil quality management, equipment acceptance, and scientific research.

Overall, the Karl Fischer (KF) method has become the internationally recognized “gold standard” for detecting moisture in transformer oil due to its high sensitivity, high precision, and standardization. In practical applications, it not only scientifically evaluates dehydrator performance but also provides reliable data support for transformer operation safety and oil quality management.

Method 3: PPM Moisture Measurement

“ppm moisture determination” isn’t a separate measurement principle. Instead, it refers to converting moisture content determined by methods such as moisture meters and the KF method into ppm (parts per million) for comparison and evaluation against industry standards. In other words, ppm is the unified measurement standard for evaluating moisture test results.

Definition and Meaning

1 ppm means 1 part water per million parts of oil sample. For the power industry, when the water content in oil exceeds 30 ppm, the insulation performance will be significantly degraded, which may cause breakdown or short circuit.

Testing Process

ppm measurement is not a single testing method, but rather a way of expressing test results. Whether using a moisture meter or the KF method, the final result is typically expressed in ppm. Engineers can use this test result to determine whether the oil quality meets operating standards.

Key Steps and Judgment Criteria

It’s important to note unit conversions. For moisture content expressed in mg/kg, 1 mg/kg = 1 ppm (approximately equivalent under standard assumptions). Before you begin, convert your instrument readings or titration calculations to ppm to facilitate comparisons across devices and methods.

International and industry standards typically use ppm as the limit for moisture content in transformer oil. For example, the IEEE C57.106 guideline recommends limits for moisture content in oil for different voltage levels (e.g., in some cases, a range of 10–30 ppm). IEEE materials on insulating oil maintenance also use 25 ppm as a reference upper limit for some voltage levels.

Finally, the transformer oil dehydration machine’s effectiveness is tested and evaluated. The ppm value is measured before and after dehydration, and the dehydration efficiency (percentage reduction) is calculated by comparison. If the post-dehydration ppm value is ≤ the recommended standard value (e.g., 10–20 ppm for high-pressure equipment), the dehydration effect is considered satisfactory. If the ppm value is still elevated, the dehydration process or equipment parameters should be analyzed for issues.

Advantages and Limitations

The advantages of this testing method are intuitiveness, uniformity, and ease of comparison across projects and equipment; it also facilitates alignment with industry standards.

However, ppm itself is not a measurement method. Results for low moisture concentrations (<1 ppm) or when the method has significant error are still limited by the measurement method itself.

Combined Application and Strategy of 3 Methods

In order to more comprehensively and reliably evaluate the actual effect of the transformer oil dehydration machine, the following combined testing strategy is recommended:

On-site Rapid Screening to Make Preliminary Judgments

Use a moisture meter to quickly measure the oil at the dehydrator outlet and compare the ppm values of the inlet and outlet oil samples. If the readings are within a reasonable range (e.g., a large difference, a significant decrease in ppm), the transformer oil dehydration machine is operating effectively within its basic dehydration state.

Precise Laboratory Verification

Oil samples from the same batch were sent to the laboratory for precise low-ppm measurement using the Karl Fischer (KF) method. Multiple repeated tests were performed and averaged to ensure reliable results.

The laboratory ppm results were compared with those from field testing instruments to evaluate the instrument’s error and stability.

Quantitative Comparison and Standard Reference

The ppm levels obtained by the two methods are compared, and a comprehensive report is generated by calculating dehydration efficiency, residual moisture content, and comparison with recommended standards.

If the post-dehydration ppm value is lower than the target standard (depending on the voltage level), the dehydrator is considered to meet the standard; otherwise, repairs or adjustments are required.

For example, you can first use a moisture detector to screen multiple tap points (inlet, middle, and outlet) to obtain a preliminary ppm distribution, and then use the KF method to analyze and confirm the suspected oil sample (highest/lowest ppm point), which saves costs and takes into account accuracy.

Conclusion

These three complementary methods—on-site testing + precise laboratory verification + ppm quantitative comparison—form a comprehensive testing system, ensuring the authenticity and reliability of the transformer oil dehydration machine’s dehydration performance.

However, before conducting any testing, it is crucial to ensure that sampling procedures are in place (e.g., sampling point, temperature, cleanliness, and avoiding hygroscopic contamination). Faulty sampling procedures can often have a greater impact than measurement errors. Numerous publications emphasize that sampling procedures are a critical prerequisite for reliable KF measurements.