Transformer Oil Regeneration vs. Replacement: Which Is More Economical?

Table of Contents

In the power industry, oil maintenance on transformers isn’t just a technical decision anymore; It’s financial and a matter of sustainability. With increasing operating costs, the power grid’s modernization, and the increase of environmental regulation, facility managers are asking the same question: With the increasing demand on cost efficient and environmentally friendly maintenance, is it more economical to regenerate transformer oil or replace it?

Why Transformer Oil Needs Regular Maintenance

Transformers rely on transformer oil to insulate, cool, and suppress arcing. But, over time, the oil can undergo oxidation, acid formation, and sludge build-up due to high temperature, moisture, and oxygen exposure. These detrimental processes can weaken insulation, age it prematurely, and cause insulation failure.

When the oil quality is subpar, operators can either replace the insulating oil with new oil or purify the oil with specific filtration and regeneration systems. The transformer oil’s current state, the detransformer’s importance, and the maintenance budget dictate the choice.

Transformer Oil Regeneration and Purification Is a Cost-effective Method for Reuse and Recycling

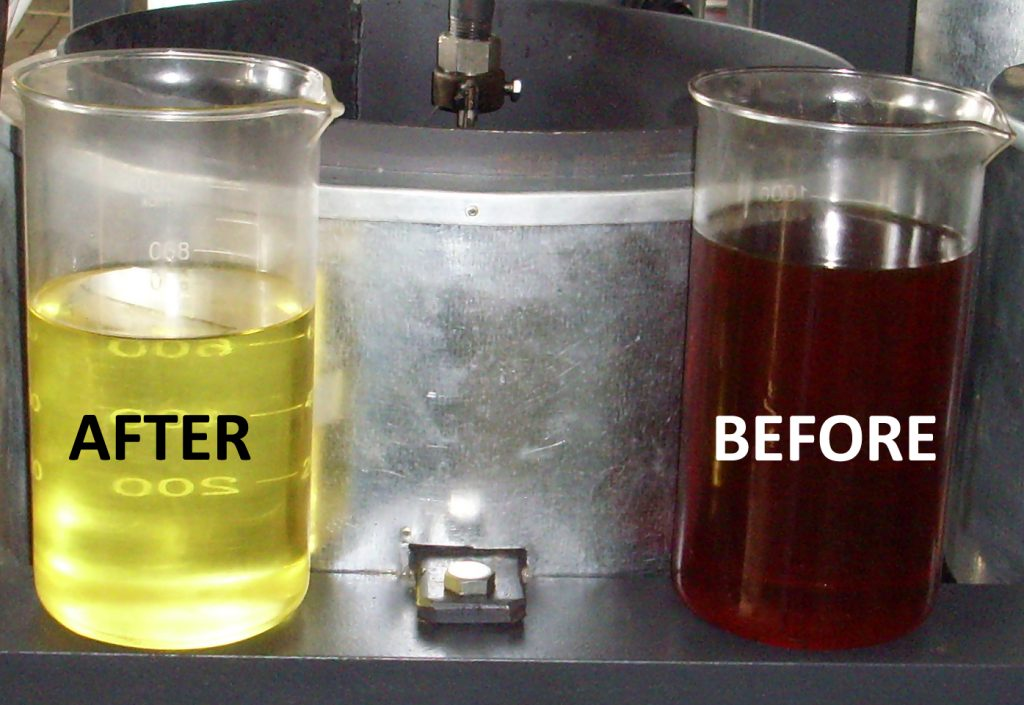

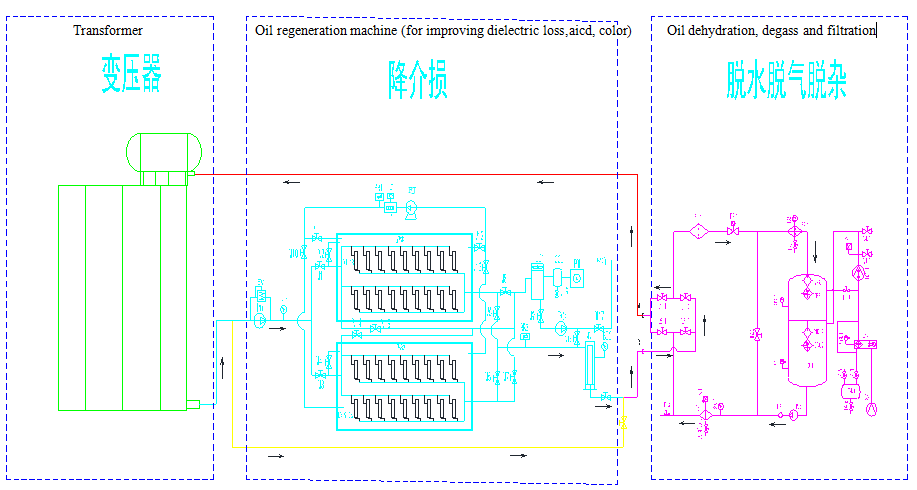

Transformer oil regeneration is a multi-stage regeneration process designed to fully restore the physical, chemical, and electrical properties of aged insulating oil. Yunneng’s purification technology combines several key steps that work synergistically to ensure high efficiency and reliability.

- Vacuum dehydration and degassing—Removes moisture, bubbles, and dissolved gases that weaken insulation strength.

- Fine filtration and particle removal—Captures micron-sized metal particles, sludge, and carbon residues, restoring oil clarity and purity.

- Adsorption regeneration treatment—Uses molecular sieves or bleaching earth to neutralize acids, reduce oxidation byproducts, and improve oil color.

- Optional heating and deacidification stages—Maintain oil stability and improve overall dielectric strength.

Together, these processes ensure that the oil’s dielectric breakdown voltage and moisture content are restored to near-new standards.

Key Advantages of Transformer Oil Purification

Based on Yunneng’s field data and expert insights into the benefits of oil purification systems, transformer oil purification offers several practical advantages to operators and maintenance teams:

For maintenance teams and power plant operators, Transformer oil purification has many unique benefits. The operational costs for oil purification is much lower than the cost for complete oil replacement, only 20-40% of the cost, and as such, it is economically viable for complete long term oil maintenance on transformers. Lastly, the purification systems developed by Yuneng which are state of the art, allow for the complete purification on-site and online, meaning no downtime occurs.

Also of importance is the fact that the method increases the life of the equipment. The oil which is treated can account for 90% of it original insulation and dielectric properties and as such, increases the service life of your transformer for many more years. Additionally, there is a lower impact on the environment as less used oil is generated and there is a sustainable method of lowering the carbon footprint in the power sector.

The design of purification systems by Yuneng is, in a class of its own, on the energy-efficient purification system. The system saves on energy and provides reliable operation as it minimizes heat loss, controls vacuum stabilization, and consistency during purification cycles.

Limitations and Practical Considerations

While purification has its benefits, it’s not a cure-all. Its effectiveness is limited when the oil is severely oxidized, contaminated with sludge, or has a high acid value. After multiple purification cycles, some additives may require partial replenishment.

Purification works best with moderately aged transformer oil, particularly those with an acid value below 0.3 mg KOH/g and a dielectric strength exceeding 30 kV/mm. For oils in even worse condition, a combination of deep regeneration and a complete oil change may be required to fully restore insulation.

Transformer Oil Replacement Is the Option for A Complete Reset

When transformer oil reaches the end of its service life, simple oil purification will not ensure electrical reliability or insulation performance. In this case, a complete transformer oil replacement is necessary. This process typically involves draining the deteriorated oil, cleaning the internal tank and cooling system, and refilling the transformer with new insulating oil that meets international standards such as IEC 60296 or ASTM D3487. Prior to refilling, the system is typically vacuum-dried to remove any residual moisture and air pockets, ensuring optimal insulation performance after the new oil is added.

Key Advantages of Transformer Oil Replacement

The primary benefit of full replacement is that it allows a transformer to experience a performance reset. New oil means replaced and restored dielectric strength, chemical stability, and thermal conductivity reset to that of a newly commissioned unit. This even holds value for seamlessly integrated critical power transformers in continuous operation, where any insulation compromise poses a possible danger.

Moreover, complete replacement provides a reset of all time-accumulated toxins, including sludge, carbon deposits, and even metallic contaminants that may evade sophisticated purification cycles. Systems with high acid values, dark oil, and bad odor are indicators of replaced oil and purification cycles.

Yet another practical aspect of full oil replacement is the consequent longer maintenance interval. New transformer oil, within the parameters of a normally defined maintenance schedule, preserves a system’s operational characteristics for eight years or more. This significantly streamlines maintenance interventions and operational costs for facility managers.

Drawbacks and Cost Considerations

Not replacing transformer oil and thus missing out on the benefits is seen as cost prohibitive and labor intensive. For large transformers, the purchase cost of oil, and the cost of waste oil removal and disposal, which must account for disposal and removal environmental regulations, can be significant. Moreover, the process requires specialized vacuum filling and degassing equipment, which adds to the costs.

Another significant cost factor is the downtime of the entire transformer system which can span one to three days. This impacts the delivery of scheduled power, inflating the costs of transformers that are critical to operations like manufacturing plants and substations.

Finally, from an environmental perspective, large volumes of waste oil oil are also difficult to dispose of. Used transformer oil contains acid sludge and metal ions which must be incinerated in specialized facilities that further escalate the costs of disposal.

When Transformer Oil Replacement Becomes Necessary

Engineers generally determine the need for oil replacement through regular oil testing and analysis. Replacement is recommended when one or more of the following conditions are observed:

- The acid value exceeds 0.5 mg KOH/g, indicating severe oxidation.

- The dielectric strength drops below 20 kV/mm, meaning the oil can no longer insulate effectively.

- The presence of heavy sludge, carbonization, or metal particles is detected in visual or chemical tests.

- Previous purification attempts fail to restore oil properties to acceptable levels.

In such scenarios, full replacement remains the most reliable and safest solution, particularly for high-voltage or mission-critical transformers where insulation failure could lead to severe damage or safety hazards.

Yuneng Role in Safe and Efficient Oil Replacement

Yuneng provides vacuum oil filtration and oil regeneration systems for transformer oil treatment. Apart from purification oil treatment, they provide assistance for full oil replacement operations. Their new oil dehydration, degassing and vacuum-filling systems help new oil attain maximum purity and dielectric strength. Regardless of whether users select oil purification or replacement, they supply the technology and equipment to ensure compliance and reliability for the foreseeable future according to global standards.

Regeneration vs Replacement: What Do the Real Costs Reveal?

To evaluate which option is more economical, let’s look at the real-world cost breakdown:

| Parameter | Oil Regeneration | Oil Replacement |

| Approx. cost (per 1000L) | $300–$500 | $1500–$2000 |

| Downtime required | 2–4 hours | 1–3 days |

| Reuse rate | 80–90% | 100% (new oil) |

| Labor intensity | Low | High |

| Environmental impact | Low | High |

| Average cost savings | 40–70% | — |

For most transformers in regular service, transformer oil regeneration can save up to 60% of total maintenance costs while maintaining acceptable oil quality.

Performance and Safety Comparison

Purified oil can restore dielectric strength to 80–95% of new oil values when processed with advanced vacuum systems. It effectively reduces moisture, acidity, and gas content to levels recommended by IEC 60422 and IEEE C57.106 standards.

While full replacement offers the highest reliability, purification is often sufficient for medium- and low-voltage transformers, provided regular monitoring is performed.

Safety note: Both methods require careful execution. Incomplete purification or improper replacement (e.g., trapped moisture or gas) can lead to insulation breakdown or partial discharge.

Environmental and Sustainability Considerations

In 2025, transformer maintenance strategies will no longer be solely about economic efficiency but also about sustainability.

Oil regeneration significantly reduces the amount of waste oil requiring disposal or incineration, thereby lowering carbon emissions and operational waste costs.

At the same time, replacement generates significant amounts of waste oil requiring regulated disposal or recycling. For utilities and industrial plants pursuing ESG (environmental, social, and governance) goals, purification better aligns with modern sustainability standards.

When to Choose Each Method: Practical Decision Guide

| Condition | Recommended Method |

| Dielectric strength > 30 kV/mm | Regenerate |

| Acid value < 0.3 mg KOH/g | Regenerate |

| Light to moderate sludge formation | Regenerate |

| Severe oxidation, dark color, foul odor | Replace |

| Oil heavily contaminated by moisture or metals | Replace |

| Limited budget or short downtime available | Regenerate |

| Critical or high-voltage transformer | Replace |

In many long-term maintenance strategies, operators adopt a hybrid approach: periodic regeneratio every few years combined with a full oil replacement every 8–10 years.

Why Choose Yuneng for Transformer Oil Treatment

As one of the leading manufacturers of transformer oil purification and regeneration systems, Yuneng provides cutting-edge solutions for high-voltage substations, power plants, and industrial users worldwide.

| Feature | Description | Key Benefit |

| Advanced Vacuum Dehydration and Degassing Technology | Removes deep-seated moisture, air, and dissolved gases from transformer oil with high precision. | Ensures stronger insulation and prevents dielectric breakdown. |

| Molecular Adsorption Regeneration | Utilizes activated clay or Fuller’s earth to restore oil color, neutralize acids, and remove oxidation products. | Revives the chemical stability and clarity of aged oil. |

| On-line Purification Options | Enables oil purification while the transformer remains in operation, without needing shutdown. | Minimizes downtime and maintains continuous power supply. |

| High Safety Standards | Fully compliant with IEC and IEEE maintenance guidelines for oil treatment equipment. | Guarantees operational safety and international compliance. |

| Customized Capacity Solutions | Offers flexible system configurations for oil capacities ranging from 600 L/h to 18,000 L/h. | Meets diverse industrial needs, from small substations to large power plants. |

Whether you need to restore, regenerate, or replace, Yuneng helps you make the most economical and environmentally responsible choice for your transformer maintenance strategy.

Conclusion

Transformer oil regeneration, or oil replacement, is vital for every transformer’s safe operation and longevity.

Nevertheless, economically, from the overall perspective, purification is the preferable option, as it replenishes functionality, and lowers expenses, downtime, and environmental consequences.

Transformers will oil purification transcend merely maintenance and become a strategic approach focused on efficiency and sustainability for the foreseeable future.