Transformer Vacuum Pump Unit: Maintaining the Heart of the Power Grid

Electricity is the lifeblood of modern society, powering everything from homes and businesses to critical infrastructure. Transformers play a vital role in this system, stepping up or down voltage levels to ensure efficient transmission and distribution of electricity. However, like any machinery, transformers require proper maintenance to function optimally and ensure a reliable power supply. Here’s where transformer vacuum pump units come into play.

Importance of Transformer Maintenance

Transformers are crucial components of the electrical grid, responsible for stepping up or down voltage levels to ensure efficient power transmission and distribution. They operate in a harsh environment, filled with insulating oil that serves two critical purposes:

- Cooling: The oil absorbs heat generated by the transformer’s internal components, preventing overheating and potential damage.

- Electrical Insulation: The oil acts as a non-conductive barrier between high-voltage electrical conductors within the transformer, preventing electrical arcing (sparking) that could cause catastrophic failure.

However, the insulating oil in transformers is susceptible to degradation over time due to several factors:

- Oxidation: Similar to how metals rust, the oil can react with oxygen in the air, leading to the formation of sludge and acidic byproducts. These byproducts can compromise the oil’s insulating properties.

- Moisture Ingress: Even small amounts of water entering the transformer can cause significant problems. Water contamination reduces the oil’s dielectric strength (resistance to electrical breakdown) and can accelerate the formation of harmful sludge.

- High Operating Temperatures: Transformers naturally generate heat during operation. While the insulating oil helps with cooling, prolonged exposure to excessive temperatures can accelerate the degradation process.

The consequences of neglecting transformer maintenance can be severe:

- Reduced Efficiency: Degraded oil loses its ability to efficiently transfer heat, leading to higher operating temperatures and increased energy losses within the transformer.

- Increased Risk of Breakdowns: As the oil degrades and loses its insulating properties, the risk of electrical arcing within the transformer significantly increases. This can lead to equipment failures, power outages, and even fires.

- Shortened Lifespan: Without proper maintenance, transformers are more likely to experience premature failure, requiring costly repairs or replacements.

Why Vacuum Drying and Pumping are Crucial?

Regular maintenance, including oil purification and vacuum drying, is essential to counteract these issues and extend the lifespan of transformers.

- Oil Purification: Specialized oil purification equipment removes contaminants like sludge, oxidation byproducts, and water from the insulating oil. This restores the oil’s insulating properties and cooling capabilities.

- Vacuum Drying: Even after purification, some moisture can remain trapped within the transformer’s insulation system. Vacuum drying addresses this issue.

Here’s a closer look at the importance of vacuum drying and pumping:

- Moisture Removal: Water is a major enemy of transformer oil. Moisture reduces the oil’s dielectric strength, making it more susceptible to electrical breakdown. Vacuum drying creates a low-pressure environment within the transformer. This significantly lowers the boiling point of water, allowing it to evaporate and be efficiently removed from the oil at a lower temperature. Lower drying temperatures minimize the risk of further oil degradation.

- Dissolved Gas Removal: During normal operation, insulating oil can dissolve small amounts of gases like air and nitrogen. These dissolved gases can form bubbles within the oil, creating pockets that reduce its effectiveness as an insulator. Vacuum drying helps remove these dissolved gases from the oil, further enhancing its insulating properties.

What is a Transformer Vacuum Pump Unit?

A transformer vacuum pump unit is a dedicated piece of equipment specifically designed to address two critical tasks during large transformer maintenance and installation:

- Efficient Vacuum Drying: This process removes moisture trapped within the transformer’s insulation system after draining the old insulating oil.

- Pumping for Oil Filling: During large transformer installations or oil replacements, the unit efficiently removes air from the transformer before introducing new insulating oil.

Here’s a more detailed breakdown of how a transformer vacuum pump unit functions:

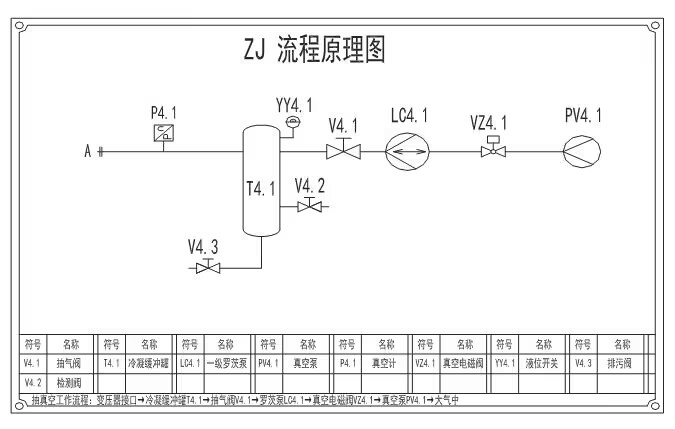

- Vacuum Pump: The core component of the unit is a powerful vacuum pump that can create a low-pressure environment within the transformer. This low pressure significantly lowers the boiling point of water and dissolved gases present within the insulating oil.

- Moisture Removal System: The unit is equipped with a system to capture and remove the evaporated moisture from the transformer. This system may involve a condenser that cools and condenses the water vapor extracted during the drying process.

- Filtration System: Some transformer vacuum pump units may also incorporate a filtration system to remove any particulates or contaminants that may be present within the transformer during the evacuation and drying process. This is customized design.

By removing air and moisture, transformer vacuum pump units play a critical role in maintaining the integrity of the transformer’s insulating oil. Here’s why these elements are detrimental:

- Air: Air pockets within the transformer can act as weak points in the insulation system, increasing the risk of electrical arcing and potential breakdowns.

- Moisture: Water contamination significantly reduces the insulating oil’s dielectric strength, making it more susceptible to electrical breakdown. Even small amounts of moisture can cause problems.

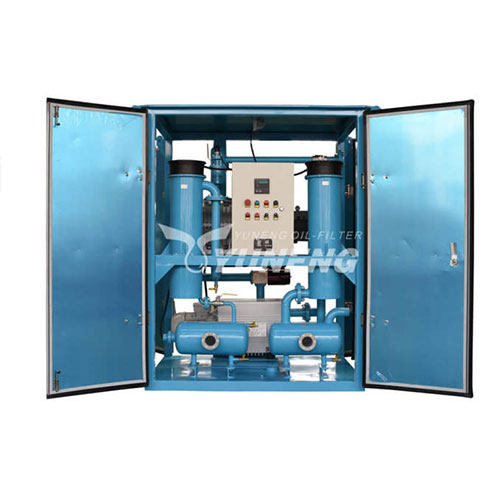

The ZJ Series: A Powerful Example

The ZJ Series from Yuneng Oil Purifier Company exemplifies a high-performance transformer vacuum pump unit. This series boasts several key features:

- High Pumping Capacity: The ZJ Series offers various models with pumping capacities ranging from 150 cubic meters per hour (m³/h) to a staggering 2000 cubic meters per hour (m³/h). This wide range caters to transformers of various sizes and oil volumes.

- Exceptional Vacuum Levels: The ZJ Series achieves exceptional vacuum levels, reaching a working vacuum of 10 Pascals (Pa). This deep vacuum ensures the thorough removal of both air and moisture from the transformer’s insulation system. Notably, it can even reach a limit vacuum of 1 Pa, further enhancing the drying process for critical high-voltage transformers.

Applications of Transformer Vacuum Pump Units

Transformer vacuum pump units serve two critical purposes in transformer maintenance:

- Efficient Vacuum Drying: During maintenance, the insulating oil within the transformer needs to be replaced. However, residual moisture can be trapped within the insulation system after draining the old oil. A transformer vacuum pump unit creates a deep vacuum within the transformer, promoting the evaporation and removal of this trapped moisture. This drying process ensures the new insulating oil operates at its peak performance level.

- Pumping for Large Transformer Installation and Maintenance: Large transformers require significant volumes of insulating oil. Transformer vacuum pump units facilitate the efficient removal of air during the oil filling process. This prevents air pockets from forming within the transformer, which could lead to electrical arcing and potential equipment failure.

Benefits of Using Transformer Vacuum Pump Units

Employing transformer vacuum pump units during transformer maintenance offers several key benefits:

- Enhanced Transformer Efficiency: By removing moisture from the insulating oil, transformer vacuum pump units prevent electrical conductivity within the oil. This maintains the transformer’s insulating properties, minimizing energy losses and maximizing overall efficiency.

- Extended Transformer Lifespan: Moisture can accelerate the degradation of the transformer’s insulation system. Effective vacuum drying helps prevent this degradation, extending the lifespan of the transformer and reducing the need for costly replacements.

- Improved Equipment Reliability: By removing air pockets during oil filling, transformer vacuum pump units minimize the risk of electrical arcing within the transformer. This translates to fewer equipment failures and disruptions to the power grid.

- Reduced Maintenance Costs: By promoting transformer efficiency and longevity, transformer vacuum pump units can help reduce long-term maintenance costs associated with repairs and replacements.

Considerations When Choosing a Transformer Vacuum Pump Unit

Selecting the right transformer vacuum pump unit requires careful consideration of several factors:

- Pumping Capacity: The unit’s pumping capacity, measured in cubic meters per hour (m³/h), should be sufficient for the size and oil volume of the transformer being serviced.

- Vacuum Level: The achievable vacuum level, measured in Pascals (Pa), is crucial. Deeper vacuums (lower Pa values) ensure more thorough moisture removal, particularly for critical high-voltage transformers.

- Operational Efficiency: Consider the unit’s energy consumption and noise levels. More efficient units will minimize operating costs and disruptions during maintenance procedures.

- Portability: Depending on the application, portability may be a factor. Some units are designed for fixed installations within transformer maintenance facilities, while others are mobile for on-site field service.

Conclusion

Transformer vacuum pump units are essential tools for maintaining the health and efficiency of transformers, the workhorses of the power grid. By removing moisture and air, these units ensure optimal insulation properties, leading to increased transformer efficiency, extended lifespan, and improved grid reliability. The ZJ Series from Yuneng Oil Purifier Company exemplifies a powerful and versatile transformer vacuum pump unit solution.