Vacuum Oil Purifier: Safe Operation and Maintenance Procedures

As an important part of the power system, transformer reliability is directly related to the stability of the power supply.

Qualitativeness and equipment life. Therefore, in order to ensure the normal operation of the transformer, it is crucial to build an oil filtering system, and the transformer vacuum oil purifier is an important equipment to solve the problem of transformer oil pollution. This article mainly introduces the safe operation and maintenance procedures of the transformer vacuum oil purifier to improve the reliability of the oil filter system and maintain the life of the transformer.

Safe Operation of Transformer Vacuum Oil Purifier

1. Inspection of equipment

Normally, before using the transformer vacuum oil purifier, a comprehensive inspection of the equipment must be carried out and its normal operation must be confirmed. The following are the specific steps:

(1) Check the appearance of the equipment for damage and foreign matter;

(2) Confirm whether the discharge valve and the oil filler port are intact and sealed;

(3) Observe whether the vacuum gauge, pressure gauge, and temperature gauge are clear;

(4) Check whether the oil pump, manual valve, electronic control valve, and oil-gas separator are normal;

(5) Test whether the transmission device is flexible and lubricate the gears and chains;

(6) Check whether the motor and electric control box are secure, and confirm whether the wire connectors are normal;

(7) Confirm whether the transformer oil level is normal.

2. Operation process

Before officially using the transformer vacuum oil purifier, the operating process should be confirmed and demonstrated based on the prototype.

Perform operations. The specific basic operation process is as follows (it will vary slightly depending on different machines):

(1) Confirm that oil pumps, valves, water tanks, water pipes, and other equipment are closed;

(2) Replace the used filter elements of the vacuum oil tank heater and filter;

(3) Clean the tank and the oil inlet pipe, and connect the oil inlet pipe to the transformer outlet;

(4) Add oil to the exhaust valve and vacuum gauge pipe interface, and open the one-way valve of the air valve in the tank door;

(5) Introduce compressed air and check whether the oil suction pipe is smooth and whether the exhaust is normal;

(6) Open the exhaust valve until the pressure in the tank reaches the working pressure;

(7) Turn on the vacuum pump, let the pointer of the vacuum gauge stabilize at 10-20kPa, and start the dynamic oil pump;

(8) During the filtration process, replace the filter element according to actual needs and drain the oil bubbles in time;

(9) After filtration, first turn off the oil pump, then turn off the vacuum pump;

(10) Close the one-way valve in the tank and clean the tank and oil inlet pipe;

(11) Add oil to the exhaust valve and vacuum gauge pipe interface, then close the exhaust valve and air valve.

Maintenance Procedures of Transformer Vacuum Oil Purifier

Even if the correct operation method is used, if we do not pay attention to maintenance, the transformer vacuum oil purifier will also malfunction, affecting our work efficiency. If you want your vacuum oil purifier to last longer, you must pay attention to maintenance. So, how should we maintain the machine? Next, I will share with you some tips on maintaining the transformer vacuum oil purifier.

- First, regularly check and replace the filter element of the vacuum oil purifier. The filter element is the core component of the vacuum oil purifier, which can filter out impurities and moisture in the oil. If the filter element is not replaced for a long time, it will cause the filter element to become clogged or damaged, affecting the filtration effect.

- Second, it is necessary to regularly maintain the vacuum pump of the vacuum oil purifier, check whether the vacuum pump oil is missing or becomes dirty and deteriorated, and replace it with new vacuum pump oil.

- Third, clean the vacuum oil purifier regularly. Cleaning the vacuum oil purifier can remove impurities and moisture remaining in the oil filter after use, ensuring the quality of the filtered oil in the later stage. It also helps to avoid clogging of the filter element due to excessive impurities, which may cause damage to the equipment.

- Fourth, the electrical equipment of the vacuum oil purifier should be checked regularly, such as heaters, contactors, etc. If there is any damage, it needs to be replaced and repaired.

- Fifth, pay attention to the use environment of the vacuum oil purifier. It should be placed in a dry, ventilated place, away from direct sunlight and humid environments.

- Sixth, during operation, you need to pay attention to whether the motor is running clockwise. Reversal will cause serious damage to the oil pump, and the oil pump will not be able to feed oil. If the motor is found to be reversed, it should be adjusted to the correct starting position immediately

- Seventh, when the running transformer vacuum oil purifier needs to be interrupted, the oil pump should be stopped 5 minutes after disconnecting the heating power supply to prevent the partial oil in the oil circuit from thermally decomposing to produce hydrocarbon gas.

The above are some basic maintenance methods for transformer oil filters. In actual operation, appropriate adjustments and supplements need to be made according to the specific equipment model and usage environment.

Precautions:

(1) During the work process, operators should remain awake, calm, and rigorous;

(2) During use, the oil bubbles should be drained in time to prevent oil spilling and spraying;

(3) Used filter elements should be disposed of in accordance with relevant environmental protection regulations;

(4) Operators should operate equipment under the guidance of professionals to prevent the occurrence of operational errors and emergencies;

(5) Operators should understand the basic principles and structure of the oil filter, and perform maintenance as required.

YUNENG Transformer Vacuum Oil Purifier

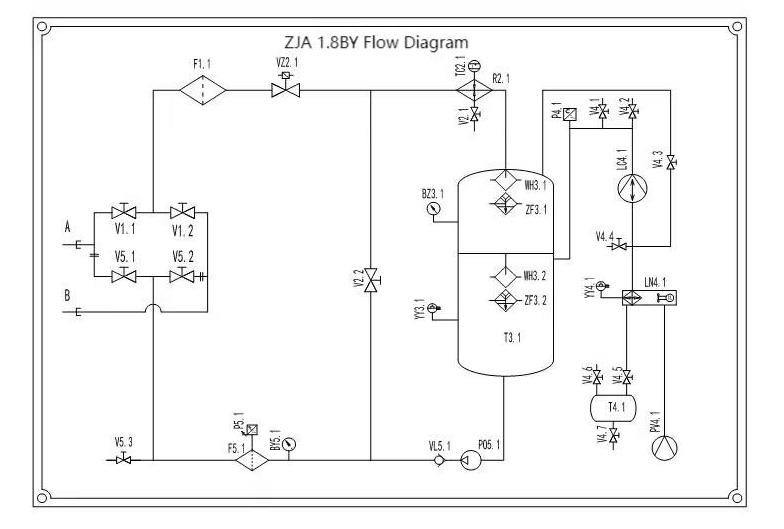

YUNENG 3000LPH Vacuum Oil Purifier is designed to dehydrate, degas, and filter transformer oil. It is suitable for use in power plants, power stations, power companies, metallurgy, petrochemicals, railways, and other industrial and mining enterprises.

The machine uses double-stage high vacuum pumping systems and a fully enclosed structure with a weatherproof canopy. The filtration process keeps the transformer oil completely clean and increases the dielectric strength of the insulating oil.

Some of the features of the 3000LPH Vacuum Oil Purifier include:

- Mobile or fixed structures

- Swivel casters

- Filter, vacuum separator, oil pump, and pipe

- Dehydration, degassing, and filtration

- Increases dielectric strength

- Can be used with a transformer oil regeneration machine decoloring device

Oil Data After Purification:

| Item | Type Unit | Guarantee indexes |

| Breakdown Voltage | KV | ≥70 (Spherical electrodes) |

| Water Content | ppm | ≤5 |

| Gas Content | % | ≤0.3 |

| Filtering Accuracy | μm | 1 |

If you have any interest in YUNENG transformer vacuum oil purifier, or have any questions, please feel free to contact us, our professional technical team will serve you wholeheartedly.