1800LPH Transformer Oil Purification Machine

- 1800LPH Transformer Oil Purification Machine is a high-quality machine.

- It is made by YUNENG, one of the best transformer oil filtration machine manufacturers in Chongqing.

- It can quickly remove water and impurities from waste transformer oil.

- This boosts the performance of transformers, circuit breakers, mutual inductors, cables, and capacitors with an insulation system.

Share to

Introduce of 1800LPH Transformer Oil Purification Machine

- 1800LPH Transformer Oil Purification Machine is a high-quality machine from YUNENG, one of the best transformer oil filtration machine manufacturers in Chongqing.

- YUNENG also produces 3000LPH transformer oil purification machines, 6000LPH high vacuum transformer oil purifier machines, and mobile transformer oil purification plants mounted on trailers.

- The machine is used to purify transformer oil for power plants, power stations, power companies, metallurgy, petrochemicals, and railways.

- It can also vacuum inject and dry electrical equipment.

- The machine quickly removes water and impurities from waste transformer oil, boosting the performance of transformers and other electrical equipment with an insulation system.

Features of 1800LPH Transformer Oil Purification Machine

- Used in the electric power system (66kV~500KV).

- Features include high working vacuum, fast oil filtering, and sound oil protection.

- Suitable for oil treatment, vacuum oil injection, and cyclic hot oil drying in the installation and maintenance of large-capacity transformers.

1800LPH Transformer Oil Purification Machine Specification

| Item | Parameter | Type Unit | ZJA1.8KY | ZJA3KY | ZJA6KY | ZJA9KY | ZJA12KY | ZJA18KY | |

| Technical Parameter | Flow Rate | L/H | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 | |

| Working Vacuity | Pa | ≤80 | |||||||

| Working Pressure | Mpa | ≤0.35 | |||||||

| Temperature Range | oC | 45-65 | |||||||

| Power Supply | 50Hz 380V 3-Phase 4-Wire (or as requested) | ||||||||

| Total Power | KW | 16 | 36 | 70 | 100 | 150 | 200 | ||

| Inlet/Outlet Diameter | DN | 20/20 | 25/25 | 32/32 | 40/40 | 50/50 | 65/65 | ||

| Size | Length | Cm | 160 | 180 | 220 | 250 | 280 | 345 | |

| Width | Cm | 125 | 145 | 160 | 195 | 215 | 260 | ||

| Height | Cm | 200 | 220 | 245 | 270 | 300 | 300 | ||

| Weight | Kg | 650 | 900 | 1200 | 1600 | 2200 | 3000 | ||

The machine size and weight will change slightly due to different configurations.

1800LPH Transformer Oil Purification Machine Working Principles

- When the transformer oil filtration plant is working, the waste transformer oil under the action of pressure difference inside and outside enters into the prefilter. The larger particles are filtered by the purifier and the oil is heated by multiple infrared rays before entering the special personalized vacuum separator. Waste transformer oil first evaporates into an oil mist in the vacuum separator and then forms a film. The contact area between the waste transformer oil and the transformer oil filter expands hundreds of times under the vacuum condition, and the water in the oil evaporates rapidly under the conditions of high heat, high vacuum, large surface, and high pumping speed and is discharged by the vacuum system.

- The steam discharged from the upper part of the vacuum separator is firstly cooled and dehumidified by the condenser and then cooled again in the cooler. The condensed water is discharged into the water storage device, and the air is finally discharged into the air by the vacuum pump after two condensations and dehumidification.

- The dry oil in the vacuum separator after vacuum vaporization and dehydration is raised from negative pressure to positive pressure through the oil pump. After secondary filtration, the clean oil is discharged from the oil outlet to complete the whole process of clean oil.

Oil Data After Filtration

| Item | Type Unit | Oil Treatment Index |

| Breakdown Voltage | KV | ≥70 (Spherical electrodes) |

| Water Content | ppm | ≤5 |

| Gas Content | % | ≤0.3 |

| Filtering Accuracy | µm | 1 |

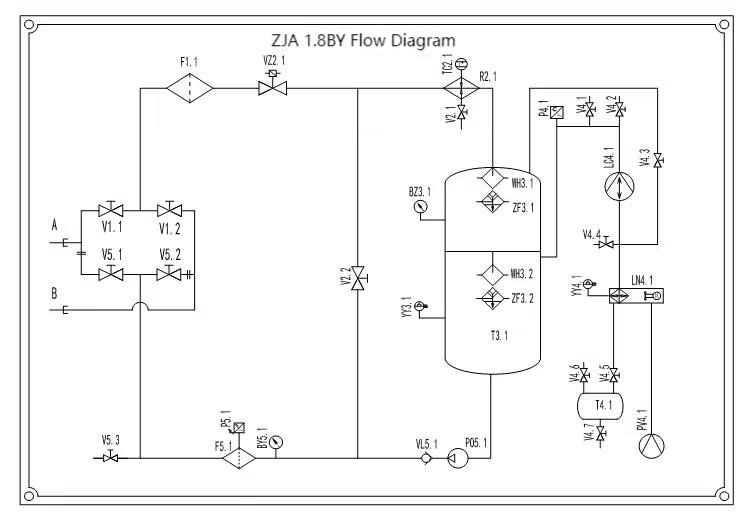

Flow Chart of Transformer Oil Purification Machine

WHY CHOOSE US

Rich Experience

Leading manufacturer in industrial oil and gas treatment with more than 25 years experiences.

Tailored Design

Specializes in making your systems suit your needs & requirements. Every system is custom engineered & custom designed.

Professional Technical Team

Professional pre-sales, in-sale and after-sales service team to meat customer’s requirement

Reliable Quality, Durable System

Top-quality components and workmanship ensure high performance