How does a double-stage vacuum oil purifier work?

Introduction of double-stage vacuum oil purifier

Double-stage vacuum oil purifier overcomes the shortcoming that a general vacuum oil purifier is only suitable for removing micro-water oil treatment. It is the most ideal special equipment for oil purification. It can remove mechanical impurities, gas, and moisture in impure oil.

Secondly, it can also improve the withstand voltage value of electrical insulating oil. Using the transformer oil in parallel to run the regeneration device can accelerate the removal of acid, free carbon, and decolorization, reduce dielectric loss, and further improve the dielectric strength of the oil. It can handle unqualified oil online. It is also possible to dry wet electrical equipment and vacuum oil.

The double-stage vacuum oil purifier achieves “large pumping speed”, that is, efficiency and rapidly increases the vacuum degree, so that the system can work in a very low vacuum state for a long time. The second is to increase the area of vacuum flash evaporation so that it can effectively and quickly break emulsification and remove water.

How does the double-stage vacuum oil purifier work?

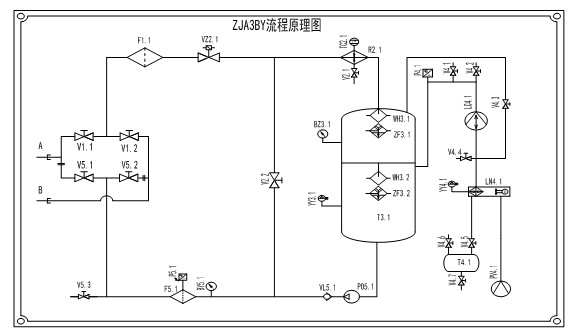

Double-stage vacuum oil purifier consists of a heater, filter, vacuum degassing tank, condenser, water tank, vacuum pump, oil discharge pump, and electrical cabinet. Now, let’s take a look at how the double-stage vacuum oil purifier works.

- V*.* Kinds of valves

- PO5.1 Oil pump

- F1.1 Primary filter

- F5.1 Fine filter

- PV4.1 Vacuum Pump

- LC4.1 Roots pump

- T3.1 Vacuum degassing tank

- WH3.1/ZF3.1 1st stage atomizer and separation column

- WH3.2/ZF3.2 2nd stage atomizer and separation column

- T4.1 water tank

- YY3.1 / YY4.1 Middle and high oil level switch

- P4.1 Vacuum meter

- P5.1 Pressure meter

- TC2.1 Temperature sensor

- R2.1 Heater

- BZ3.1 Vacuum gauge

- BY5.1 Pressure gauge

The to-be-purified oil enters into primary filter through the oil inlet valve under the negative pressure. The big impurities is filtered out and then the oil is transferred to heaters for heating up to the certain temperature by using the automatic constant-temperature digit-display controller. After then the oil is transferred into the double-stage vacuum degassing chamber.

The hot oil is burst and atomizing through the atomization injector, so it forms the oil film step by step with a great extended area in the double high efficient separation tower.

The water and gas in the oil is vaporized in extremely short time under high vacuum status, which leads to the separation of oil from water and gas.

The separated vapor and harmful gases enter into the condenser and become water which can be discharged from the machine after a certain time.

The extracted oil is then pumped by the special oil delivery pump and transferred through the fine filter to remove the mechanical particles in the oil.

The oil characteristics will be improved and meet the requirements after circulating filtration.

Therefore, to meet the higher processing requirements, the double-stage vacuum oil purifier needs to meet the following conditions:

1. High vacuum, ultimate vacuum≤5Pa, working vacuum≤80Pa.

2. Patented technology with stainless steel double stage vacuum degassing tank which can quickly remove water and gas.

3. Large pumping speed

4. Heater can be divided in group control.

5. Impurity removal technology combining primary filter and fine filter

6. Oil flow can be adjusted by VFD

7. Suitable for vacuum oiling and vacuum drying of power transmission and transformation equipment above 110KV.

Reliable double-stage vacuum oil purifier

There are many types of double-stage vacuum oil purifiers. Here is a reliable double-stage vacuum oil purifier that you can choose from, which is a 6000LPH high vacuum transformer oil purifier machine. This oil purifier has a high working vacuum and can quickly purify the oil. It is suitable for power transmission and transformation equipment above 220kV. The working pressure is less than or equal to 0.35Mpa and the working vacuity is less than or equal to 80Pa. The breakdown voltage of this oil purifier is greater or equal to 70KV. The water content is less than or equivalent to 5ppm. The gas content is less than or equal to 0.3 percent. The filtering accuracy is 1µm. Thus, the 6000LPH high vacuum transformer oil purifier machine can be a reliable double-stage vacuum oil purifier to purify transformer oil.