How Transformer Vacuum Drying Works & Why It’s Critical for Performance

The transformer is a common component widely used in industrial production and daily life. However, the transformer is easily affected by the environment during installation or transportation, which causes the transformer to be damp. Transformer dampness will affect the normal operation of the transformer, and even the service life of the transformer. The safe and reliable operation of the transformer affects the normal operation of the power system.

This article will introduce the vacuum operation of the transformer by vacuum drying and vacuum oiling in detail.

Introduction to Vacuum Oil Injection

Vacuum oil injection is a critical process in transformer maintenance, offering substantial benefits for both transformer longevity and the overall stability of the power system. The presence of bubbles in transformer oil poses a threat to normal operation, potentially affecting the entire power system. Vacuum oil injection addresses this issue by employing advanced technology to reduce and eliminate air bubbles in the oil.

This process significantly improves the insulation level of transformer oil, preventing breakdown accidents and enhancing the overall dielectric strength. By extracting impurities and gases, vacuum oil injection ensures a homogeneous and purified oil, contributing to prolonged transformer life. The reliability and safety of the power system are further bolstered as the vacuum process minimizes disruptions caused by air bubbles.

In essence, vacuum oiling plays a pivotal role in maintaining transformer health, promoting efficient power transmission, and preventing potential failures. The process is indispensable for safeguarding the transformer’s operational life and supporting the seamless functioning of the entire power infrastructure.

What is the Vacuum Drying Process?

Transformers contain various insulating materials, vital for electrical performance. Water entering the transformer can compromise insulation, affecting normal operation and safety. Moisture can expand materials, alter sizes, and impact electrical strength. Vacuum drying is crucial in manufacturing, transportation, and post-flooding maintenance to maintain optimal insulation, ensuring the reliable functionality of power equipment like transformers. This process is essential for both insulating materials and transformer oil.

Here is an overview of the vacuum drying process for transformers:

- Preparation: Before initiating the vacuum drying process, the transformer is carefully prepared. This involves thorough cleaning and inspection to ensure there are no contaminants or foreign particles within the insulation.

- Initial Heating: The transformer is heated initially to a moderate temperature, causing the moisture within the insulation to turn into vapor. This step prepares the insulation for the subsequent vacuum drying phase.

- Vacuum Application: Once the initial heating is complete, a vacuum is applied to the transformer. The vacuum serves to lower the pressure inside the transformer, facilitating the removal of moisture vapor at lower temperatures than would be required under normal atmospheric pressure.

- Moisture Removal: With the vacuum in place, the temperature is raised further. The combination of vacuum and elevated temperature promotes the efficient removal of moisture from the insulation material. The vaporized moisture is drawn out by the vacuum system.

- Cooling Phase: After the majority of the moisture has been removed, the transformer is gradually cooled down. This step is essential to prevent rapid cooling, which could lead to the condensation of any remaining moisture.

- Final Inspection: Following the vacuum drying process, the transformer undergoes a final inspection to ensure that the specified moisture content levels have been achieved. Various diagnostic tests may be conducted to confirm the effectiveness of the drying process.

How to Assess if Insulation is Good?

There are three properties that we can use to assess whether insulation is good.

- Resistance to Electrical Current: The effectiveness of insulation is determined by its resistance to electrical current. Higher resistance indicates superior insulation, limiting current flow, while lower resistance suggests suboptimal insulation with an increased risk of current leakage.

- Dielectric Strength of Insulator: The dielectric strength assesses a material’s ability to act as an insulator, measuring the maximum voltage per unit thickness before breakdown. A higher dielectric strength signifies superior insulation, showcasing the material’s capacity to withstand higher voltages and ensuring better insulating quality.

- Dielectric Loss: Dielectric loss quantifies the energy dissipated over time by a dielectric material under an electric field. The commonly used dielectric loss tangent value, denoted as tan delta or dielectric loss factor, serves to measure the magnitude of dielectric loss. Lower tan delta values indicate reduced energy dissipation, reflecting improved insulation performance. These three properties collectively offer a comprehensive assessment of insulation quality, crucial for maintaining electrical efficiency and preventing potential breakdowns.

How to Carry Out the Drying Process of the Transformer?

Insulation parameters are affected by the water content in the insulating material. The lower the water content in the insulating material, the better the insulating properties can be obtained. The drying process is the process of removing moisture from the insulating material. The insulation can be dried to some extent by heating the insulation and evaporating the water in the insulation.

However, the process of drying the insulating material by heating may damage the physical and chemical properties of the insulating material. The transformer also cannot evaporate water from the insulation by heating alone. This can damage the physical properties of the transformer and can also have dangerous consequences.

Therefore we need to carry out the drying process of the transformer without heating the transformer insulating material. Drying of insulating materials in transformers can be achieved at low temperatures and low voltage levels. At low pressure or vacuum, the process of water evaporation is accelerated if enough heat is supplied to the insulating material. Therefore, in a vacuum environment, we can more easily achieve drying of insulating materials.

It is a scientific and simple choice to vacuum dry or evacuate power transformers through the transformer vacuum pump system.

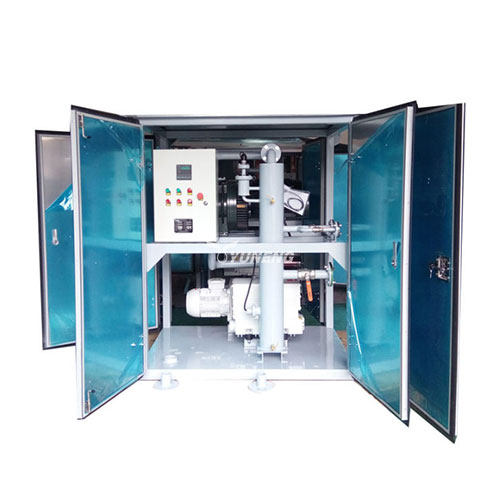

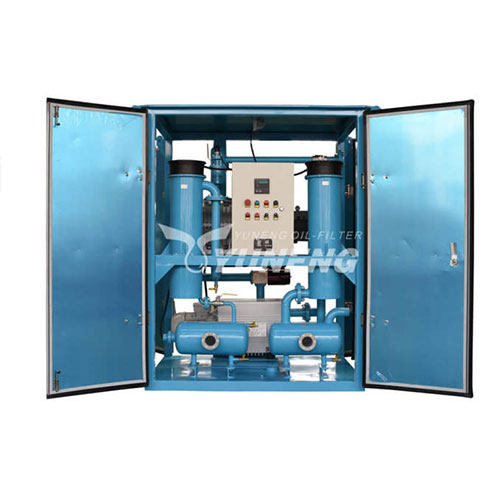

Transformer Vacuum Pump System Produced by YUNENG

The transformer vacuum pump system produced by YUNENG is mainly suitable for vacuum oil filling and vacuum drying of various large power transformers such as 220kV, 500kV, ±800kV, and 1000kV.

The vacuum degree of the machine’s working can reach 10Pa, and the ultimate vacuum degree can reach 1Pa. The transformer evacuation system with vacuum pump produced by YUNENG has the advantages of simple operation and stable performance, and also has the advantages of fast startup, high pumping speed, and preventing suck back.

If you have questions about the transformer vacuum pumping system, you can contact us at any time. YUNENG can provide you with professional solutions according to your specific needs.