Vacuum Pumping Systems and Their Role in Transformer Maintenance

Table of Contents

The contemporary electricity network predominantly utilizes power transformers in upgrading and downstepping the voltage. Their effectiveness and durability as a crucial asset are solely reliant on the intactness of the internal insulation, which consists of oil and solid insulating materials such as paper and pressboard. Moisture and the presence of gases within the insulation are leading causes of premature aging, loss of dielectric strength, and catastrophic failure. Such intrusive and harmful materials require specialized and highly efficient systems to extract them.

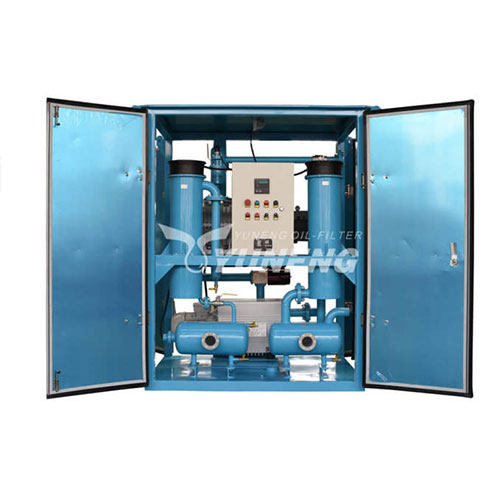

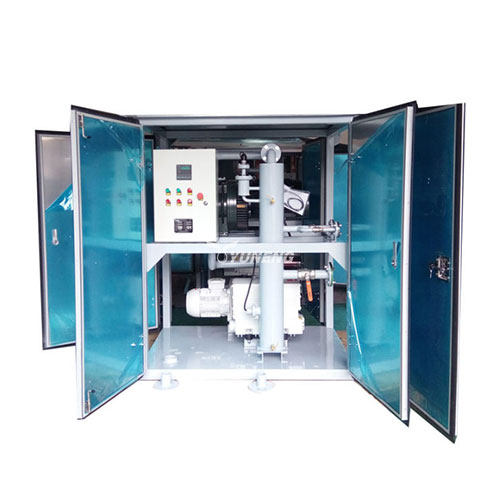

This problem is solved by a vacuum pumping system, which is an industrial machine designed for deep vacuum drying and efficient vacuum pumping. These systems are essential in the installation and scheduled maintenance of large transformers. Industry leaders like YUNENG, an established vacuum pump and oil purification power equipment manufacturer, provide diverse vacuum pump systems to comply with the standards set in the Power Industry. The primary aim of these systems is to extend the asset’s operational life and maintain its operational performance by removing air, moisture, and other contaminants from the transformer tank and insulation.

How is the Vacuum Pumping System Working?

The basic principle of a vacuum pumping system is to bring down the atmospheric pressure in a closed transformer tank to a point where the moisture contained in the transformer begins to evaporate at relatively low temperatures. This is called vacuum drying. At the same time, the system discharges all non-condensable gases in the transformer and prepares it for the subsequent vacuum oil-injection process.

What are the Pumping System Technical Features?

YUNENG systems, for instance, are exemplary, top-tier systems, whose advanced functionalities are governed by a set of operationally pivotal technical features that fuel ease-of-use and effectiveness maximally:

- Fast Air Extraction and System Start-Up: Designed for swift system start-up, the system’s pumping speed is exceptionally fast (fast air extraction). This advanced air evacuation capability in the system is a critical driver in vacuum for transformer condenser to speed up the process of vacuum level attainment. Absence of downtime is significant of the completion of the pre-established benchmarks of the installation and maintenance projects.

- Energy Efficiency: The latest tank units do not compromise pumping capacity. In addition, they are low energy consuming, and operationally cost efficient in regard to the system flow control to the equipment’s lifespan.

- Advanced Monitoring and Control: User convenience and precision control are critical. The systems are heavily controlled vacuum systems. The operators incorporating them can easily maintain and control complex vacuum systems. The parameters controlled include critical factors like Pressure Control. Pressure Levels. Systems Operation status. And so on. The LCD units help monitor those.

- Flexible Design and Maneuverability: These systems are used on transformers. Such as at bay and other work sites. The designs emphasize portability and flexibility. This helps move systems easily between different stopping points. The robust compact build is mostly mobile. All these factors help deploy systems across numerous work environments.

- Stable and Reliable Performance: The last and max critical point is. The system must maintain a stable performance under continuous operation. This achieves the shallow level ultimates and maximum. Consistent operation also helps maintain the pumping rate.

Classification of Yuneng Vacuum Pump Units and Specialized Units

A vacuum pump unit is a piece of equipment that covers a large array of operating functions for which a vacuum is generated and along with a customised class of transformer that is modular to a set size and a set voltage.

The standard vacuum pump unit of the ZJ series is the fundamental unit of the complete range. These units are classified as the workhorses of vacuum drying and vacuuming. They are extensively deployed in the installation and routine servicing of medium and large-sized transformers. Packaged to optimise the unit economics, the ZJ series delivers enhanced productivity and profitability in the market, as well as durable and field-tested reliability.

Ultra high voltage transformers that are custom vacuum designed for the ZJ series high vacuum pump. Specialized systems are needed to obtain a highly ultra deep vacuum for ultra high voltage transformers. They are configured for the severe demands of all high voltage electrical transformers.

To achieve and maintain ultra low absolute pressure, many advanced units feature a two-stage transformer vacuum pump with a Roots pump in the advanced systems. The Roots pump, or mechanical booster pump, increases the pumping speed in the low pressure zone and within the primary vacuum range, which enhances the vacuum speed the most, and is, thus, the most effective for quickly reducing pressure for large high voltage equipment where final vacuum is needed.

The primary determinant of speed for the system is the capacity in m³/h, which converts set volume to time for evacuation. A range of YUNENG products includes:

- 150 m³/h Vacuum Pump: Used with smaller power transformers or for field maintenance.

- 500 m³/h Double Stage Transformer Evacuation System: Medium size becomes a common scale for mid-range transformers.

- 1000 m³/h Transformer Vacuum Drying Machine: Serves larger equipment, designed to boost the processing speed of bigger apparatus.

- 2000 m³/h Transformer Drying Vacuum Pump Set: Fastest evacuation of most large UHV transformers, emphasising fast start and high pumping rate, which is critical for large units.

Common Uses in Vacuum Processing of A Transformer

Vacuum pumping systems are crucial in starting up and maintaining a transformer.

1. Vacuum Drying (Moisture Removal)

There is a need in the process of vacuum drying, which comes from the hygroscopic nature of the solid insulation of the transformer. Even the smallest amounts of moisture in the insulation diminish the dielectric strength and speed its thermal degradation. The system starts the process by lowering the pressure, thus enabling moisture trapped in the cellulose to vaporise. This is the principle on which the transformer vacuum drying machine functions, where, under a vacuum, the boiling point of water drops to a lower level. This ultra-deep, low-temperature vacuum is the only process that does not thermally stress the insulation, thus resulting in the removal of deep-seated moisture.

2. Transformer Evacuation and Oil Injection

After the drying phase, the transformer has to be filled with insulating oil under vacuum conditions. This process is the work of the transformer evacuation system, which serves two purposes.

- Removal of Gas: We have to ensure that there is no air and residual gases in the tank and windings. This is to ensure there is no partial discharge activity when the unit is activated.

- Complete Impregnation: If an oil tank is maintained under high vacuum and oil is injected, the fibrous insulation is fully penetrated, and no air bubbles are trapped because of the high vacuum. It is very important to the EHV/UHV systems that pumps like the 150m3/h vacuum pump for power transformers can do vacuum drying and then, injection of oil directly to high voltage transformers, including 1000kV, for ultra high voltage systems.

3. Broader industrial applications

Deep vacuum generation principles extend the use of these systems to other high-precision industries, even beyond the power sector. The versatile transformer evacuation system is beneficial to vacuum smelting, chemical pharmacy, welding, and the production of electric vacuum devices, along with multiple other devices, showcasing its use beyond grid maintenance.

Conclusion: Elevate Your Grid Reliability with Yuneng

Much more than a simple pump, the vacuum pumping system is a sophisticated multifunctional device, which forms an integral part of the complex system of critical electrical infrastructure of utmost importance, ensuring operational integrity. These systems, with the help of advanced vacuum configurations like the ZJ Series with Roots Pumps, achieve and maintain ultra-deep vacuum levels, facilitate efficient vacuum drying, and ensure flawless oil impregnation. Improved grid reliability and reduced maintenance costs, coupled with extended transformer life, are what these systems promise.

If you are seeking to minimize transformer downtime, achieve unparalleled deep vacuum for your 1000kV apparatus, and ensure decades of reliable service, choose the proven efficiency of Yuenng’s specialized vacuum pumping systems.

Stop compromising on quality. Contact Yuneng today to request a quote, explore our ZJ Series units, and secure the definitive solution for your transformer evacuation and drying needs.