Application of Purification and Recycling Technology in Transformer Oil Purification Industry

Amidst the continuous optimization of global energy structures and increasingly stringent environmental protection policies, transformer oil purification and recycling technologies are becoming a key innovation in transformer maintenance. Especially with the widespread deployment of high-voltage transmission systems, smart grids, and large-scale substations, maintaining stable transformer oil performance has become a critical component in ensuring the safe operation of power systems.

Table of Contents

Importance and Pollution Issues of Transformer Oil

Transformer oil is not permanently stable. Its long-term contamination and degradation are becoming a widespread risk in the global power industry. Neglecting quality management can have profound impacts on transformer lifespan, operating efficiency, and even the entire power grid.

The Critical Role of Transformer Oil in Power Systems

Transformer oil is a specialized oil used for insulation, cooling, and arc extinguishing in high-voltage transformers. It performs several critical functions during equipment operation:

Electrical insulation: Prevents electrical breakdown between the windings and the core, ensuring the stability of the high-voltage structure.

Heat exchange and cooling: Absorbs heat generated by the windings and core and dissipates it through a circulation system.

Arc buffering and arc extinguishing: Helps absorb arc energy and suppress arc expansion during sudden load changes or short-circuit faults.

Protecting insulation materials: By blocking oxygen and moisture, it slows the aging of insulation paper and materials.

According to IEEE (Institute of Electrical and Electronics Engineers) Standard C57.106, stable, high-performance transformer oil can extend equipment life by 8-10 years and significantly reduce failure rates, providing the invisible foundation for long-term, stable substation operation.

The Prevalence and Hidden Nature of Contamination Issues

Although transformer oil is stable, it is susceptible to contamination from various internal and external factors during actual operation, including:

Moisture: Ingress of humid air from respirators, condensation, or during maintenance can severely affect insulation performance;

Oxidation products: Prolonged exposure of oil to air at high temperatures can form acids, colloids, and precipitates;

Particulate contamination: Contamination such as metal shavings, carbides, and insulation fragments can damage equipment and clog cooling systems;

Dissolved gases: Contamination such as hydrogen, methane, and acetylene is the result of partial discharge and thermal decomposition.

According to a report by the CIGRÉ (International Conference on Large Electric Systems) Technical Study Group A2.34, over 65% of transformer failures worldwide are related to oil degradation. Even minor contamination can cause the oil’s breakdown voltage to drop by more than 20% under high-voltage conditions, significantly reducing its insulation protection capabilities.

Typical Risks of Contamination

Continued operation of contaminated transformer oil not only degrades the oil’s performance but can also lead to the following serious consequences:

Insulation breakdown: Moisture and acidic products significantly reduce the oil’s breakdown voltage, causing insulation failures such as partial discharge and flashover.

Hotspot formation and heat dissipation failure: Deposits and particles hinder heat exchange, leading to heat accumulation and localized overheating of the windings.

Increased corrosion: Oxidation products corrode copper and insulation paper, damaging the coil and core structure.

Failure chain reaction: Bubbles in the oil can form micro-explosions under high pressure, triggering arcing, equipment shutdown, and even explosion.

For example, in 2020, a main transformer at a 500 kV substation in Germany exploded. An investigation revealed that the cause of the accident was moisture and particulate contamination in the oil exceeding three times the IEC 60422 standard limit, directly resulting in a loss of electrical strength in the oil and thermal breakdown in the equipment. This caused a nearly eight-hour power outage and resulted in losses exceeding €4 million.

Furthermore, according to a 2022 report by the International Energy Agency (IEA), the failure rate of power equipment due to oil quality deterioration continues to rise annually globally, with the problem being particularly severe in regions with a high proportion of older equipment.

Transformer oil is not only a critical medium for the normal operation of power equipment but also the first line of defense for system safety. However, its susceptibility to contamination and rapid performance degradation necessitate proactive and regular oil condition monitoring and purification. Based on global practical experience, promoting transformer oil circulation purification, online regeneration, and intelligent monitoring will be crucial for achieving sustainable power system operation.

Principles and Advantages of Recycling Technology

As global power equipment operating life increases and the demand for sustainable operations grows, the traditional “dirt-and-replace” model is gradually being replaced by more efficient and environmentally friendly recycling solutions. According to the “Global Waste Oil Assessment Report 2021″ jointly released by the International Energy Agency (IEA) and the United Nations Environment Programme (UNEP), approximately 39 million tons of waste mineral oil are generated globally each year, including a large amount of insulating oil from transformer systems. However, less than 40% of this waste is formally recycled and reused, while the majority is incinerated or illegally dumped, resulting in significant waste of the environment and resources.

Technical Principle

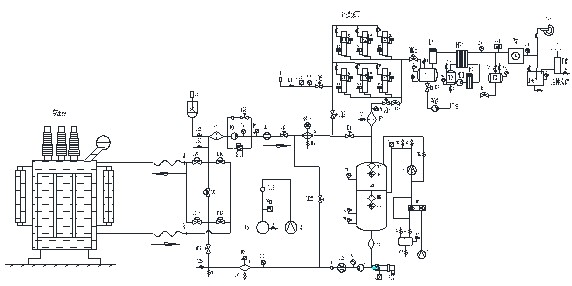

Transformer oil recycling technology goes beyond simple filtration. Instead, it involves a multi-step, systematic treatment process combining physical separation, chemical adsorption, catalytic reduction, and intelligent monitoring to restore the oil’s electrical properties and extend its service life. A typical process flow is as follows:

- Vacuum Dehydration & Degassing: Under negative pressure, free water, dissolved water, and various gases (such as H₂, CH₄, and C₂H₂) are removed from the oil, reducing the water content to <10 ppm and effectively improving the oil’s dielectric strength. Standard Reference: IEC 60422 (2013) Clause 5.6

- Fine Filtration: The multi-stage filtration structure removes particulate matter ≥1μm, preventing the accumulation of carbonized particles caused by wear and discharge.

- Active Adsorption & Catalytic Regeneration: High-surface-area adsorbents (such as activated clay, molecular sieves, and Al₂O₃ catalysts) are used to chemically adsorb and reduce acidic oxidation products and soluble polar impurities, effectively restoring the oil’s neutralization value, color, and dielectric loss factor (tanδ).

- Smart Monitoring & Automation: Online conductivity, temperature, and water content monitoring modules enable dynamic adjustment of process parameters and fault warnings, improving process accuracy and safety.

According to CIGRÉ Technical Brochure No. 771 (2020), the complete regeneration process can restore the oil’s insulation properties to new oil standards (breakdown voltage > 70 kV, total acid number < 0.05 mg KOH/g). Regeneration can be repeated two to three times, significantly reducing procurement and replacement costs.

Technology Optimization and Industry Application Results

Many power companies and equipment manufacturers around the world have invested in the research and development and industrialization of this technology, demonstrating its adaptability and cost-effectiveness, particularly in the field of high-voltage, large-capacity power transformers. For example:

- Germany’s Siemens Energy completed the deployment of an online oil recycling and purification system across its 45 substations in 2021. Data shows that the overall oil regeneration cost is 60% lower than replacing new oil, and the amount of waste oil disposed of is reduced by 1,500 tons annually.

- India’s National Power Transmission Corporation (NTPC) has been using localized regeneration equipment since 2020, regenerating over 3,000 tons of transformer oil annually and achieving cumulative cost savings of approximately US$4.5 million.

- A DuPont research report indicates that oxidation products in recycled mineral oil are reduced by over 85%, significantly reducing the corrosion rate of insulation paper, effectively extending the transformer’s operating life by 3-5 years.

At the same time, technology manufacturers are pushing purification equipment towards modularization, miniaturization, mobility and AI-driven analysis systems, which facilitate distributed processing and remote monitoring on site, further reduce manual intervention and improve operation and maintenance efficiency.

Green Sustainable Value

Compared to traditional barrel replacement, recycling not only avoids the incineration or dumping of tens of tons of waste mineral oil, reducing carbon emissions and resource waste, but also supports the long-term strategy of “healthy operation” of transformers by restoring their performance. According to the EU EN 15380 standard, compliant recycled transformer oil is structurally identical to virgin oil, allowing continued use in high- and ultra-high-voltage transformers.

This technology is increasingly becoming a key tool for power grid companies worldwide to fulfill their ESG goals and green energy commitments, focusing on carbon footprint management, lifecycle cost control, and resource recovery.

Key Technical Components and Equipment Upgrades

- Vacuum Dehydration System: Reduces oil pressure, allowing water and gas to escape rapidly. Modern equipment can control water content to below 5 ppm, well below IEC standards.

- High-precision Multi-stage Filter: Effectively removes particles ≥ 1 μm, protecting transformer windings from mechanical wear.

- Activated Clay Adsorption Column: Excellent adsorption capacity for polar impurities and oxidation products, restoring oil color and stability.

- Online Monitoring and Remote Control System: Enables real-time monitoring of oil quality indicators and remote operation, improving operational efficiency and safety.

Leading manufacturer YUNENG has developed a range of advanced transformer oil purification systems that support fully automated regeneration and multi-oil-type compatibility. These systems are specifically engineered to meet the evolving needs of smart maintenance across major utility operators, including high-voltage substations, power plants, and grid service providers.

Conclusion

YUNENG solutions are widely adopted in large-scale transformer operations where continuous, efficient oil recovery is critical. With features such as PLC control, real-time monitoring, and modular mobility, YUNENG equipment enables operators to reduce manual intervention, lower operational costs, and comply with international sustainability benchmarks.