The Importance of Transformer Oil BDV Test to Power System Safety

In transformers, BDV oil tester of insulating oil is an important means of ensuring its dielectric strength. As the oil ages or becomes contaminated, its dielectric strength decreases, resulting in reduced insulation performance of the equipment and increasing the risk of electrical failure.

Table of Contents

The Importance of Transformer Oil BDV Test

Ensuring Electrical Safety

The BDV value of transformer oil is an important indicator to consider as oil quality can affect performance. Low BDV values can be an indicator of aging insulation which can lead to undesirable electrical incidents like short circuits and electric arc discharges. Damage from these issues can affect and destroy the transformer and can also lead to fires. Conducting the transformer oil BDV test on a scheduled basis ensures that a properly maintained schedule is adhered to and that proactive methods like replacing transformer oil can be done before an electrical accident takes place.

Enhancing Equipment Reliability

A high BDV value indicates that the transformer oil can be operated without breakdown at higher voltages without suffering breakdowns, thus improving the transformer’s operational stability. Within the electric grid, the reliable functioning of transformers is essential in maintaining the seamless flow of electricity. Failure to meet the BDV specification of transformer oil can result in the transformer suffering unanticipated shutdowns while operating under normal conditions, resulting in unexpected outages which translate to significant costs. With the transformer oil BDV test, the insulating properties of the oil can be assessed, thus providing assurance that the oil meets the transformer’s insulating standards, enhancing the transformer’s reliability, minimising equipment unavailability, and reducing maintenance expenses.

Compliance with Industry Standards

Compliance with industrial standards, such as ASTM D1816 and IEC 60156, is necessary for the results of the transformer oil BDV test. These standards outline minimum BDV requirements for transformer oil, which is around 30 – 40kV for new oil. If the BDV results indicate less than the benchmark, the transformer oil is either required to be replaced or undergo some sort of treatment. Through rigorous BDV tester, the oil can be confirmed to meet industry standards and therefore, guarantee the safety of the power system.

Preventive Maintenance

The transformer oil BDV test (Breakdown Voltage Test) is used in diagnostic and predictive maintenance; in fact, it is part of an oil laboratory analysis. By supervising the BDV value of transformer oil, it is possible to identify issues and then take action to remediate the transformer oil (replace or treat) before they escalate. Furthermore, the trend analysis of the BDV value can also estimate the ageing and contamination rate of the transformer oil. For instance, a steadily declining trend might signal gradual deterioration of the oil quality, while an abrupt drop might indicate a more serious underlying issue. Detecting these problems allows a more actionable and timely approach, allowing the Maintenance Technicians to perform proper servicing, such as filtration, drying, or replacement, thereby extending the transformer’s lifespan and lowering servicing expenses.

Other Important Tests for Transformer Oil

| Test Item | Test Content | International Standard | Unit | Notes |

| Visual Inspection | Check the transparency and foreign matter in the oil to determine contamination. | ASTM D1524 | – | Poor transparency, foreign matter, or turbidity indicates contamination. |

| Color Analysis | Compare the color of the oil sample to check for darkening, indicating contamination or internal arcing. | ASTM D1500 | 0 – 5 (color value) | Darker oil may indicate contamination or internal faults. |

| Dissolved Gas Analysis (DGA Test) | Analyze dissolved fault gases in the oil to identify thermal and electrical stresses inside the transformer. | ASTM D3612 | ppm (gas concentration) | Different gases indicate different types of stress. |

| Dissolved Metals | Measure dissolved metals in the oil to identify metals caused by overheating, arcing, or mechanical wear. | ASTM D7151 | µm (micrometers) | Measured using ICP-AES. |

| Flash Point or Ignition Point | Test the volatility of the oil to determine the lowest temperature at which it can ignite. | ASTM D92 | ℃ | Ensures the safety of the oil. |

| Interfacial Tension | Identify the presence of soluble contaminants and oxidation products in the insulating oil. | ASTM D971 | mN/m | Lower values indicate higher contamination. |

| Furan Compounds | Measure furan compounds produced by cellulose materials in the oil, indicating insulation aging. | ASTM D5837 | – | Measured using HPLC. |

| Moisture Content | Test the moisture content in the oil to assess insulating performance. | ASTM D1533 | ppm | Ideal value < 35ppm; higher moisture reduces insulating strength. |

| Neutralization Number or Acid Number | Measure the acid content in the oil to identify oxidation or contamination. | ASTM D974 | mg KOH/g | New oil typically has no acid content. |

| Polychlorinated Biphenyls (PCB) Content | Test for PCBs in the oil to ensure environmental compliance. | ASTM D4059 | ppm | Measured using gas chromatography. |

| Pour Point | Determine the lowest temperature at which the oil flows to ensure proper operation in cold climates. | – | ℃ | Important for transformers in cold regions. |

| Relative Density | Measure the relative density of the oil to identify suspended water. | ASTM D1298 | – | High values indicate the presence of suspended water. |

| Resistivity | Test the resistivity of the oil to assess insulating performance. | – | Ω (ohms) | Low resistivity indicates conductive contaminants in the oil. |

Factors Affecting the BDV Value of Transformer Oil

Several factors can influence the breakdown voltage (BDV) value of transformer oil. Understanding these factors is crucial for interpreting BDV tester results accurately and implementing measures to maintain the oil’s insulating properties.

| Factor | Description | Impact on BDV |

| Moisture Content | Water is a common contaminant in transformer oil. It can enter the oil through poor seals, condensation, or leakage. | Even trace amounts of moisture can significantly reduce the oil’s dielectric strength. |

| Particles and Sediments | Solid impurities such as dirt, dust, and metallic particles can reduce the BDV. | These particles act as conductive paths, facilitating a breakdown in the insulating properties of the oil. |

| Dissolved Gases | Gases like oxygen and other reactive gases can form due to transformer operation or oil oxidation. | Dissolved gases can degrade the oil’s dielectric properties and reduce the BDV. |

| Age and Oxidation | Over time, transformer oil undergoes chemical changes due to oxidation and exposure to high temperatures. | These changes result in a breakdown of the oil’s molecular structure, leading to reduced BDV values. |

| Temperature | The temperature of the oil can affect its BDV. | Higher temperatures generally result in a lower BDV, as the oil’s viscosity and insulating properties are reduced. |

| Electrode Geometry | The design and configuration of the electrodes used in the BDV testing cell can influence the test results. | Proper calibration and maintenance of the testing equipment can help minimize variations due to electrode geometry. |

| Test Procedure | Adherence to standardized testing protocols such as ASTM D1816 or IEC 60156 is crucial. | Deviations from the prescribed procedures can lead to inconsistent or inaccurate readings. |

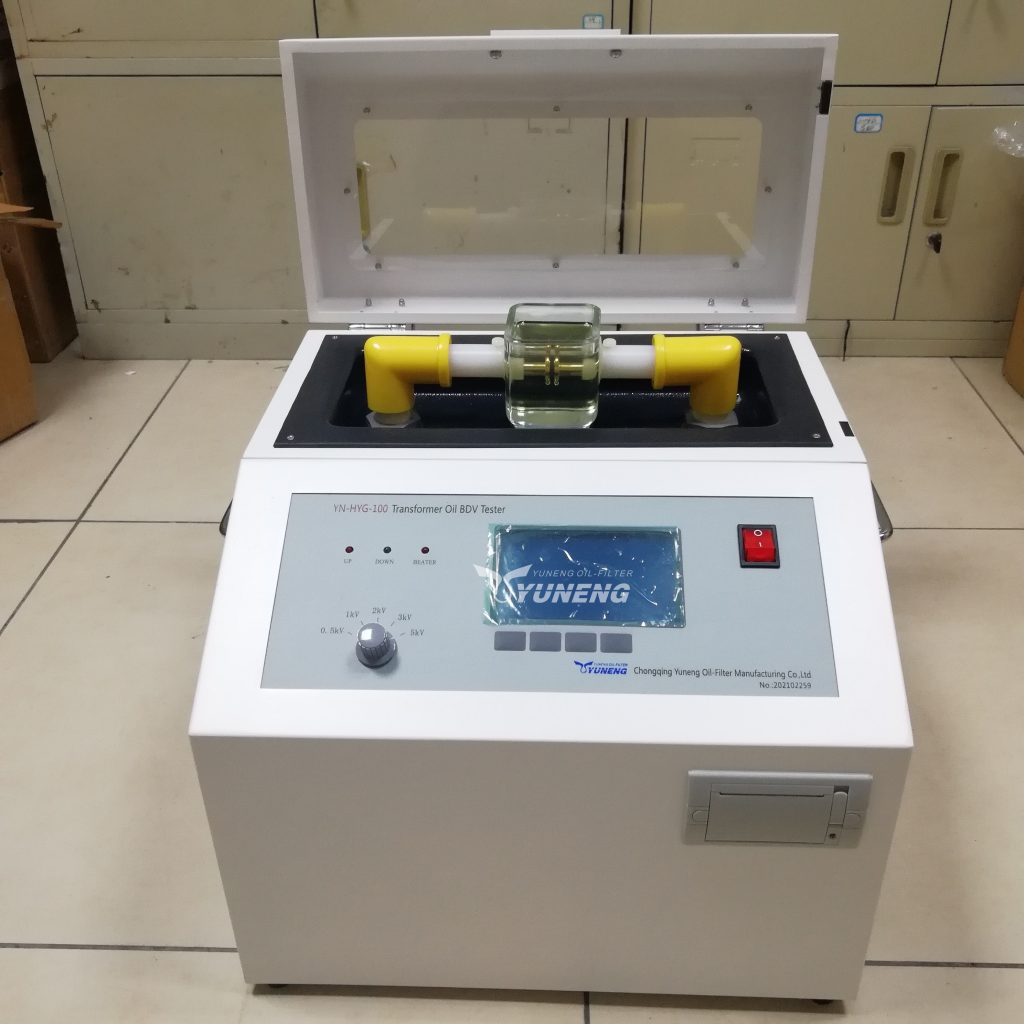

Why Choose the IEC Standard Transformer Oil BDV Tester from YUNENG

When it comes to ensuring the accuracy and reliability of your transformer oil BDV tests, choosing the right equipment is essential. The IEC Standard Transformer Oil BDV Tester from YUNENG is designed to meet the highest standards of precision and durability. Here’s why you should consider this advanced testing solution:

- Rich Experience: YUNENG is a leading manufacturer in industrial oil and gas treatment, with over 25 years of experience.

- Tailored Design: Specializes in custom – engineered solutions to meet your specific needs and requirements.

- Professional Technical Team: YUNENG offers comprehensive pre – sales, in – sales, and after – sales services to ensure customer satisfaction.

- Reliable Quality: Top – quality components and workmanship ensure high performance and durability.

Invest in the IEC Standard Transformer Oil BDV Tester from YUNENG to ensure accurate, reliable, and efficient testing of your transformer oil. Visit YUNENG to learn more about this advanced testing solution and how it can benefit your operations.