Transformer Oil Purification System and Vacuum Transformer Oil Purifier

Transformers are crucial in the electrical power industry, but they require regular maintenance to ensure longevity. High-quality, clean oil is essential for transformers to operate efficiently.

Over time, transformer oil degrades due to exposure to contaminants such as acids, metal dust, and moisture. When the oil contains dissolved gases, dust, and other impurities, it becomes necessary to filter and purify the oil.

Maintenance and service centers use advanced equipment and transformer oil purification systems to treat the oil. These techniques help maintain excellent performance, enhance safety, and facilitate ease of operation for maintenance personnel.

What are the types of transformer oil?

Transformer oils, also known as insulating oils. There are several main types of transformer oils.

1. Mineral Oil-Based Transformer Oil

Mineral oil is the most common type of transformer oil, derived from refined crude oil. There are two main subtypes of mineral oil-based transformer oils:

- Naphthenic Oil: Naphthenic oils have good low-temperature properties and are stable at low temperatures. They have lower pour points and better solvency for polar contaminants, making them suitable for use in colder climates.

- Paraffinic Oil: Paraffinic oils have higher oxidation stability and are more suitable for high-temperature applications. However, they have higher pour points compared to naphthenic oils, which can be a disadvantage in very cold environments.

2. Synthetic Oils

Synthetic transformer oils are man-made and offer superior performance compared to mineral oils in certain applications. They include:

- Silicone Oil: Silicone oils are known for their excellent thermal stability and fire resistance. They are used in transformers located in high-risk areas where fire safety is a major concern. Silicone oils also have a wide operating temperature range and are less affected by temperature changes.

- Ester-Based Oils: Ester oils can be either natural (biodegradable) or synthetic. They have high fire points and good biodegradability, making them environmentally friendly. Natural esters, derived from vegetable oils, are especially popular for use in environmentally sensitive areas. Synthetic esters offer similar benefits but with improved performance and stability.

Transformer Oil Purification Method

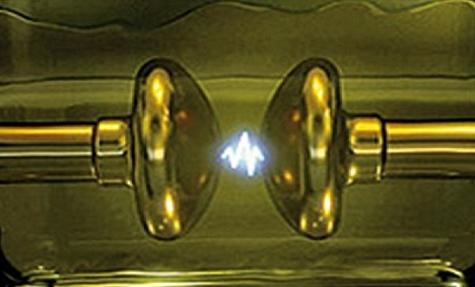

When the temperature of transformer oil increases to more than 65 degrees Celsius, the latent heat causes moisture and gases within the oil to separate. This heat-induced separation lowers the oil’s viscosity, facilitating the efficient removal of contaminants. Following this process, sludge and dirt are extracted using filter candles, which function either as edge filters or depth filters. Additionally, filter cartridges and edge-type paper filters are employed to ensure thorough cleaning.

Centrifugation is another method used to separate dirt from the oil. This approach is cost-effective as it does not require frequent replacement of filters, thereby saving money. After these purification steps, the oil is directed to a degassing chamber. Here, any remaining gases are removed, ensuring the oil is in optimal condition to support the effective functioning of transformers.

The resulting high-quality oil significantly extends the transformer’s lifespan, reduces the likelihood of transformer failure, and enhances the return on investment. This improved efficiency and reliability not only minimize operational disruptions but also contribute to increased profitability by reducing maintenance costs and enhancing the overall performance of the electrical system.

YUNENG Transformer Oil Purification System

YUNENG Transformer Oil Purification System helps to improve the insulating ability and dielectric strength of the transformer oil. This can lead to better performance and efficiency of the transformer.

Transformer oil degrades over time due to exposure to heat, air, and electrical stress. Our system helps to remove contaminants that can accelerate this degradation process, thus extending the life of the transformer oil and reducing the need for costly oil replacements.

The YUNENG system is designed to remove a wide range of impurities from transformer oil, including:

- Solid particles: These can be things like dirt, rust, and metal shavings. The presence of solid particles in transformer oil can increase the risk of electrical arcing and faults.

- Dissolved gases: Dissolved gases in transformer oil can be an indication of overheating or incipient faults. The YUNENG system can help to remove these gases, improving the health of the transformer oil.

- Water: Water contamination can significantly reduce the insulating ability of transformer oil. The YUNENG system can effectively remove water from transformer oil.

Overall, the YUNENG Transformer Oil Purification System can help to improve the performance, efficiency, and lifespan of transformers by removing impurities that can degrade the quality of the transformer oil.

What are the Types of Vacuum Transformer Oil Purifiers?

The vacuum transformer oil purifier is an important tool for transformer maintenance. They effectively remove dissolved gases and moisture from oil using high vacuum technology, restore their insulation performance, and extend the lifespan of transformers. There are many types of vacuum transformer oil purifiers that can meet different needs, here are some main types:

1. Mobile Vacuum Transformer Oil Purifiers

- Compact and trailer-mounted, making them ideal for on-site oil purification at transformers.

- Perfect for routine maintenance or emergency situations where transformers are spread across a geographical area.

- Often have a smaller processing capacity compared to other types.

2. Skid-Mounted Vacuum Transformer Oil Purifiers

- Larger and more powerful than mobile units, typically mounted on a skid for easy transportation.

- Designed for processing large volumes of oil, often used in substations or power plants with multiple transformers.

- May have additional features like multiple stages of filtration or integrated regeneration capabilities.

3. Batch Purification Vacuum Transformer Oil Purifiers

- Stationary units ideal for processing oil from transformers undergoing maintenance in a workshop setting.

- Offer the highest processing capacity among the three types.

- May be equipped with features for faster processing or handling heavily contaminated oil.

4. Double-Stage Vacuum Transformer Oil Purifiers

- A specialized type that utilizes a two-stage vacuum process for enhanced oil purification.

- The first stage removes bulkier contaminants and moisture, while the second stage creates an even deeper vacuum for superior degassing.

- Ideal for heavily contaminated oil or situations requiring exceptionally high oil quality.

5. Oil Regeneration Systems

- Some vacuum transformer oil purifiers can be integrated with oil regeneration capabilities.

- This additional stage removes acids and other impurities from spent oil, allowing for its reuse and reducing waste.

Find A Good Vacuum Transformer Oil Purifier

Transformer oil filtration is highly beneficial for businesses. Therefore, having quality transformer oil filtration equipment is essential. Many companies provide various types of equipment, but it is important to select a vendor that produces high-quality insulation oil purification machines to ensure a high return on investment (ROI).