How Does Oil Reclamation Extend the Life of Your Power System?

For the smooth operation of any power system, transformer oil plays a vital role. Acting as both an insulator and coolant for critical electrical components, its quality directly impacts system efficiency and longevity. However, transformer oil degrades over time, leading to a cascade of problems if left unchecked.

This article explores the importance of transformer oil reclamation and how investing in a dedicated reclamation machine can significantly benefit your business.

Why Need Transformer Oil Reclamation?

Transformer oil, the lifeblood of your power system, performs a vital two-fold function: insulation and cooling. It acts as a non-conductive barrier between high voltage components, preventing electrical arcing and catastrophic equipment failure. Simultaneously, it circulates within the transformer, absorbing heat generated during operation and dissipating it through radiators.

However, transformer oil isn’t invincible. Over time, several factors contribute to its degradation, leading to a domino effect of problems if left unchecked. Here’s a closer look at the major culprits behind oil deterioration and their consequences:

- Oxidation: Exposure to air, particularly at elevated temperatures experienced during normal transformer operation, triggers oil oxidation. This process breaks down the oil’s molecular structure, producing harmful byproducts like acids, sludge, and water.

- Thermal Stress: Transformers naturally generate heat during operation. Excessive thermal stress, caused by overloading or inadequate cooling, accelerates oil oxidation and the formation of contaminants.

- Moisture Ingress: Even small amounts of moisture entering the transformer, through faulty seals or condensation, can have a significant impact. Water reduces the oil’s insulating properties and promotes the growth of microorganisms that further degrade the oil.

The consequences of neglecting transformer oil reclamation are severe and can lead to:

- Increased Electrical Losses: Contaminated oil loses its insulating efficiency, allowing a portion of the electrical current to leak as heat. This translates to higher energy bills and increased strain on your power grid.

- Accelerated Equipment Aging: Degraded oil acts like a poor conductor of heat. This traps heat within the transformer, causing it to operate at higher temperatures. Similar to constantly running a car engine hot, this significantly accelerates the aging process of transformer components, leading to costly breakdowns and potential replacements.

- Outtages and Equipment Failure: Severe oil contamination can lead to a complete breakdown of the transformer’s insulating properties. This can trigger arcing, short circuits, and catastrophic equipment failure. Not only does this result in power outages and production downtime, but replacing a large power transformer can be a significant financial burden.

By proactively implementing transformer oil reclamation, you can prevent these costly consequences and ensure the continued health and efficiency of your power system.

Signs You Need Transformer Oil Reclamation

Transformer oil reclamation, also known as transformer oil regeneration or reconditioning, is a process used to restore the properties of degraded or contaminated transformer oil to its original specifications. Signs indicating the need for transformer oil reclamation typically revolve around the deterioration of the oil’s quality and performance. Here are some signs that may suggest the need for transformer oil reclamation:

- Decreased Dielectric Strength: The transformer oil’s primary function is to insulate and cool the transformer. Over time, contaminants such as moisture, particles, and oxidation by-products can reduce the oil’s dielectric strength, increasing the risk of electrical breakdown. If routine tests reveal a decrease in dielectric strength, it may signal the need for oil reclamation.

- Increased Moisture Content: Moisture is one of the most common contaminants in transformer oil. High levels of moisture can accelerate the degradation of the insulation system and reduce the oil’s dielectric properties. Monitoring moisture content through regular testing can help identify the need for oil reclamation.

- High Levels of Dissolved Gases: Dissolved gases, such as hydrogen, methane, and ethylene, are produced as a result of the breakdown of insulation materials and oil. Monitoring and analyzing dissolved gas levels can provide insights into the condition of the transformer and the oil. Elevated levels of certain gases, such as acetylene and ethylene, may indicate abnormal thermal or electrical stresses and signal the need for oil reclamation.

- Presence of Particulate Matter: Particles and contaminants can enter transformer oil through various sources, including dust, moisture, and degradation of internal components. Accumulation of particulate matter can lead to increased wear and tear on transformer components and reduce the effectiveness of the oil. Regular oil analysis can detect the presence of particles and indicate the need for reclamation.

- Color and Odor Changes: Visual inspection of transformer oil can sometimes reveal changes in color and odor, indicating the presence of contaminants or degradation products. The darkening or cloudiness of the oil, along with unpleasant odors, may suggest the need for reclamation to restore the oil’s cleanliness and performance.

- Increased Oxidation: Oxidation of transformer oil occurs when it reacts with oxygen, leading to the formation of acids, sludge, and other degradation products. Elevated levels of oxidation by-products can accelerate aging and reduce the oil’s effectiveness. Regular testing for acidity and oxidation products can help assess the need for oil reclamation.

- Decreased Breakdown Voltage: Breakdown voltage, also known as dielectric breakdown voltage, is a measure of the oil’s ability to withstand electrical stress without breaking down. A decrease in breakdown voltage over time indicates a decline in the oil’s dielectric properties and may necessitate reclamation to restore its insulating capabilities.

These signs and indicators are valuable tools for assessing transformer oil conditions and determining whether recycling is needed to maintain the reliability and performance of power transformers. Regular monitoring, testing, and proactive maintenance can help reduce the risk of transformer oil degradation or contamination.

Benefits of Using A Transformer Oil Reclamation Machine

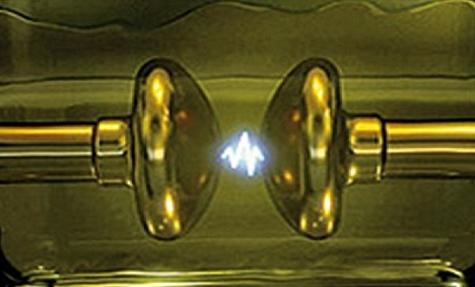

YUNENG Transformer Oil Reclamation Machine is a state-of-the-art solution designed for the purification and regeneration of transformer oil, aimed at extending the lifespan and improving the performance of transformers. This advanced machine utilizes reactivated regeneration filters to efficiently remove contaminants, moisture, and oxidation by-products from transformer oil, restoring it to its original specifications.

Key features and benefits of the YUNENG Transformer Oil Reclamation Machine include:

- Reactivated Regeneration Filters: The machine is equipped with reactivated regeneration filters that efficiently remove impurities and contaminants from transformer oil. These filters are designed to be regenerated, providing cost-effective and sustainable purification solutions.

- High Efficiency: YUNENG Transformer Oil Reclamation Machine is engineered for high efficiency, ensuring thorough purification of transformer oil to meet stringent quality standards. It effectively removes moisture, gases, particulate matter, and oxidation by-products, restoring the oil’s dielectric strength and insulating properties.

- Versatility: The machine is versatile and can be used for various types of transformer oils, including mineral oil, silicone oil, and synthetic ester oil. It is suitable for transformers of different sizes and capacities, offering flexibility and adaptability to diverse applications.

- Advanced Technology: YUNENG utilizes advanced technology and innovative solutions in its Transformer Oil Reclamation Machine, ensuring optimal performance and reliability. The machine incorporates precision filtration, degassing, and dehydration processes to achieve superior purification results.

Overall, YUNENG Transformer Oil Reclamation Machine offers a comprehensive solution for the purification and regeneration of transformer oil, helping to prolong the lifespan of transformers, improve reliability, and reduce maintenance costs. With its advanced features, efficiency, and versatility, it is a preferred choice for industries and utilities seeking high-quality oil purification solutions.

Conclusion

In summary, maintaining high-quality transformer oil is crucial for power system efficiency. This article emphasizes the significance of transformer oil reclamation and introduces the YUNENG Transformer Oil Reclamation Machine as a top-notch solution. By proactively reclaiming transformer oil, businesses can prevent costly consequences like increased electrical losses and equipment failures. The YUNENG machine offers high efficiency, versatility, and advanced technology, ensuring prolonged transformer lifespan and improved performance.

If you are in any need of Transformer Oil Reclamation Machine, please feel free to contact YUNNEG.