What Impact Does the SF6 Gas Recovery Device Have on the Environment

Due to environmental pollution and atmospheric damage, environmental protection concepts are becoming more and more popular. As the core of energy supply, the power industry is also actively exploring the path of sustainable development. SF6 (sulfur hexafluoride) gas is favored for its excellent performance and is widely used as an insulation and arc extinguishing medium for high-voltage electrical equipment. However, SF6 is also a potent greenhouse gas, and its impact on the environment cannot be ignored. Fortunately, with the advancement of technology, the emergence of SF6 gas recovery equipment provides an effective solution to this problem.

Table of Contents

SF6 Gas Recycling Can Reduce Greenhouse Gas Emissions

SF6 has a global warming potential (GWP) 23,900 times higher than that of carbon dioxide, which means its contribution to the greenhouse effect is extremely significant. During the operation and maintenance of power equipment, the leakage and emission of SF6 gas can have a severe impact on the environment. However, by using SF6 gas recovery equipment, these gases can be efficiently recovered and reused, thereby significantly reducing greenhouse gas emissions.

For example, YUNENG SF6 gas recovery, purification, and filling plant can achieve a gas purity of more than 99.95% after recovery, which fully complies with the 60376 standard of the International Electrotechnical Commission (IEC). This advanced SF6 gas recovery technology not only significantly reduces greenhouse gas emissions but also helps companies save up to 30% of potential costs. In this way, power companies can achieve a win – win situation of economic and environmental benefits while meeting environmental protection requirements..

Improved Resource Utilization Through SF6 Gas Recycling

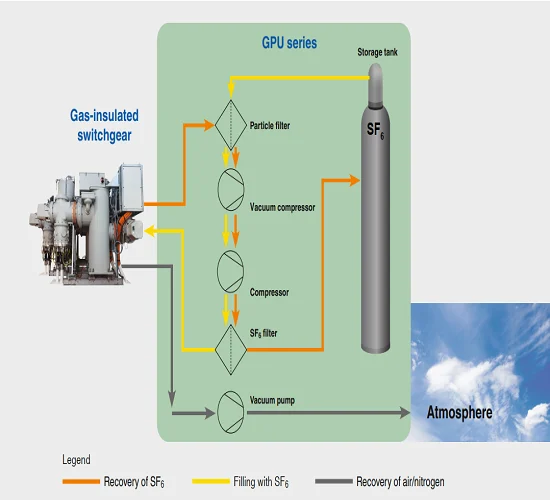

SF6 gas is used in large quantities in power equipment, but traditional methods often cause waste due to gas leakage and emissions during equipment maintenance and renewal. The emergence of SF6 recovery devices allows these gases to be efficiently recovered and purified, thereby achieving multiple cycles.

For example, the SF6 ReUse project of the US Environmental Protection Agency (EPA) demonstrated the high efficiency of SF6 gas recovery through a case study. The project minimizes SF6 gas emissions during operation by optimizing the recovery process and adopting advanced purification technology. This efficient SF6 gas recovery not only reduces gas waste, but also significantly reduces the operating costs of enterprises. Through the recovery device, power companies can better manage SF6 gas resources, optimize inventory, reduce equipment downtime caused by gas shortages, and improve equipment operation efficiency.

Reduce the Environmental Impact of Equipment Maintenance

During the maintenance of power equipment, traditional methods may cause SF6 gas leakage and environmental pollution. To address this, power companies use SF6 recovery devices to effectively reduce such leakage. Before dismantling the equipment for maintenance, technicians recover all the gas using the recovery device, prohibiting direct discharge into the atmosphere. They then load the recovered gas into cylinders marked with the recycled gas logo and transport it to a special processing center for purification.

This practice not only reduces gas waste but also prevents environmental pollution caused by gas leakage. In this way, power companies can minimize their environmental impact during equipment maintenance while ensuring the safe operation of the equipment.

Reduce Emissions of Toxic Decomposition Products

SF6 gas may decompose in the equipment due to arc or partial discharge, producing some toxic and corrosive decomposition products, such as HF, SO₂, SOF₂, etc. These decomposition products are not only harmful to the equipment, but also have potential harm to the environment and human health.

In order to avoid threats to the environment and human health to a greater extent, during the operation of the equipment, SF6 gas is regularly purified to remove possible toxic decomposition products. At the same time, SF6 gas recovery equipment is used to recover gas when the equipment is overhauled or scrapped to prevent toxic decomposition products from being directly discharged into the environment.

Comply with Environmental Regulations

With the global emphasis on environmental protection, many countries and regions have formulated strict regulations on the use and emission of SF gas. The use of SF6 recovery devices can ensure that companies comply with these regulations and avoid high fines for illegal emissions. For example, the International Electrotechnical Commission (IEC) 62271-4 standard specifies the recovery and treatment process of SF6 gas in detail, requiring the recovery and recycling of 99% or more of SF6.

By adopting SF6 gas recycling systems, power companies can not only meet the requirements of environmental regulations, but also enhance the company’s social image and sustainable development capabilities.

Promote Circular Economy

The SF6 recovery device not only reduces gas waste, but also promotes the development of circular economy. By recycling and reusing SF6 gas, the demand for new gas can be reduced and resource consumption can be reduced. For example, the recycled SF6 gas can be used to manufacture new switchgear products, realizing the closed-loop utilization of resources.

This circular economy model not only helps to reduce resource waste, but also reduces the operating costs of enterprises and improves the economic benefits of enterprises.

Reduce the Emission of Other Pollutants

During the SF6 gas recovery process, some pollutants may be generated, such as equipment noise pollution, solid waste pollution, tail gas treatment wastewater, and laboratory testing waste liquid. By optimizing the recovery process and taking appropriate treatment measures, the emission of these pollutants can be effectively reduced. For example, the use of advanced recovery equipment and technology can minimize the noise pollution during equipment operation, and at the same time properly handle solid waste and liquid waste to avoid secondary pollution to the environment.

Conclusion

The emergence of SF₆ recovery devices provides the power industry with an effective solution to deal with the potential threat of SF6 gas to the environment. By efficiently recovering and reusing SF6 gas, not only can greenhouse gas emissions be significantly reduced, but also resource utilization can be improved, the impact of equipment maintenance on the environment can be reduced, the emission of toxic decomposition products can be reduced, environmental regulations can be met, the development of a circular economy can be promoted, and other pollutant emissions can be reduced.

With the continuous advancement of technology and the enhancement of environmental awareness, the application of SF6 recovery devices will become more and more extensive. As a leading manufacturer of SF6 recovery devices and related equipment, YUNENG provides reliable and efficient solutions for the power industry with its outstanding innovation capabilities and unremitting pursuit of high-quality products. By adopting YUNENG’s advanced equipment, power companies can not only achieve a win-win situation in economic and environmental benefits, but also make positive contributions to global environmental protection.