What is a Transformer Vacuum Pump for Transformer Drying?

The oil-immersed transformer is an important piece of equipment in modern power networks, and the safety of equipment operation has a direct impact on the power supply network.

Insulation drying treatment affects the overall performance of oil-immersed transformers, so it is necessary to pay attention to the insulation drying process of oil-immersed transformers. In actual work, it is found that the transformer vacuum drying process has a good application effect in the insulation drying treatment of oil-immersed transformers, which can improve the production efficiency of the transformer factory.

This article will introduce the transformer vacuum pump for power vacuum transformer drying and vacuum oil filling in detail from various aspects.

What are Transformer Vacuum Pumps for Drying?

A Transformer Vacuum Pump plays a pivotal role in various industrial applications, offering versatility in tasks ranging from transformer vacuuming and drying to vacuum smelting, welding, chemical processes, pharmaceutical manufacturing, and power vacuum devices. In the context of drying transformers, these pumps are instrumental in creating a vacuum within the transformer, facilitating the removal of moisture and gases from the insulating materials. By effectively reducing the pressure in the transformer, the vacuum pump accelerates the evaporation of residual moisture, ensuring that the insulation maintains its intended dielectric properties.

Beyond the realm of transformer drying, these pumps find application in vacuum smelting processes, where they create the necessary low-pressure environment for the efficient extraction of impurities from metals. Additionally, they contribute to various industrial processes, showcasing their adaptability and significance across a spectrum of applications critical to diverse industries.

What is Power Transformer Vacuum Drying & Why Transformer Vacuum Drying Process is Needed?

The body of a transformer comprises essential components such as the iron core, coil, and insulating material assembly. This assembly is critical for the transformer’s efficient functioning. When a transformer comes into contact with water, the insulating material’s performance is compromised, leading to a reduction in its insulation capabilities. This not only jeopardizes the normal operation of the transformer but can also result in severe safety hazards.

To mitigate these risks and ensure optimal performance, transformers undergo a crucial step known as transformer vacuum drying after assembly but before the addition of transformer oil. This process is imperative for removing moisture and gas from the insulating material. By carefully controlling the moisture content within the specified limits outlined by product quality requirements, the transformer’s dielectric strength is preserved, contributing to its overall operational life.

The primary objective of power transformer vacuum drying is to eliminate moisture present in the transformer’s insulating material. This meticulous process enhances the efficiency, reliability, and service life of the transformer, safeguarding its critical role in electrical systems and preventing potential breakdowns or safety issues.

What is Transformer Vacuum Oiling?

Transformer vacuum oiling is a critical procedure in the final stages of transformer manufacturing or during maintenance. In this process, the transformer is sealed and connected to a vacuum pump to create a vacuum, effectively removing air and gases from the insulation materials. Once the vacuum is established, insulating oil is introduced into the transformer, taking advantage of the vacuum to ensure thorough impregnation of the insulation. This step is essential for solid insulation materials, such as paper. The vacuum oiling process enhances the dielectric strength of the insulation, reduces the risk of partial discharges, and contributes to the overall efficiency and longevity of the transformer. Additionally, the oil used for vacuum oiling is typically filtered to maintain cleanliness and prevent impurities from affecting the insulating properties of the oil.

During the normal oil filling of the transformer, in order to remove the gas during the oil filling process, vacuuming is a more effective measure. Contains two methods:

- When there is no oil in the tank: in a vacuum state, slowly inject qualified transformer oil from the bottom of the tank.

- When the oil tank of the transformer is full of oil: at this time, the whole transformer is evacuated and degassed.

The purpose is to separate the gas inside the transformer from the insulating medium and improve the insulation level of the transformer.

Why Do You Need a Transformer Vacuum Pump?

The Transformer Vacuum Pump holds a crucial role in the comprehensive maintenance and manufacturing processes associated with large power transformers, particularly those operating at high voltage levels such as 220KV, 500KV, ±800KV, and 1000KV. Its primary applications include facilitating the vacuum drying process during the assembly of these transformers and conducting the vacuuming operation necessary for the subsequent filling of insulating oil. This pump is highly suitable for deployment in diverse settings, including power plants, substations, and transformer manufacturing plants.

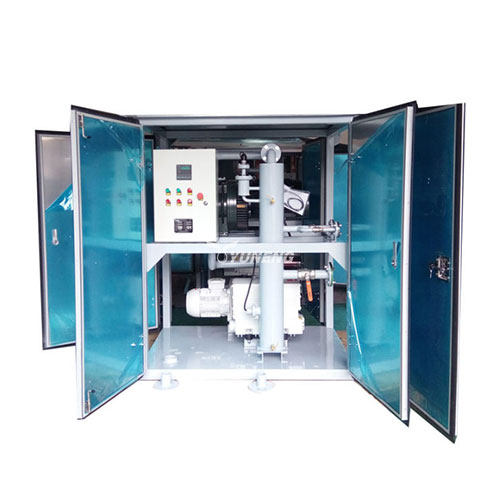

The transformer vacuum pump system is characterized by several advanced features that enhance its efficiency and usability. With functions like fast air extraction, the pump ensures rapid and thorough removal of air and moisture from the transformer, which is crucial for maintaining optimal insulation properties. Its low energy consumption aligns with sustainability goals, providing an environmentally friendly solution for vacuuming operations. The inclusion of an LCD display adds a layer of user-friendly interface, allowing operators to monitor and control the vacuuming process with precision. Moreover, the system’s flexible movement capabilities contribute to its adaptability in different operational environments, making it a reliable and versatile tool in the realm of transformer maintenance and manufacturing.

What Are the Characteristics of a Transformer Vacuum Pump?

- The Transformer Vacuum Pump is designed with essential features, including an anti-suck back to prevent reverse flow, quick start for efficient operation initiation, high pumping speed for rapid vacuum creation, stable performance for consistent results, and easy operation for user-friendly control during various applications.

- Notably, the primary vacuum pump within the transformer vacuum pump system is sourced from renowned international brands, emphasizing top-tier quality and reliability in its construction and performance.

- Offering exceptional capabilities, the vacuum pump achieves a working vacuum as low as 10Pa and an ultimate vacuum of 1Pa. The intelligent vacuum setting feature enables precise control, allowing users to tailor the vacuum levels to meet specific requirements.

- The pump exhibits flexibility by providing the option to reserve Gas Insulated Switchgear (GIS) interfaces based on customer preferences. This customization ensures compatibility with various transformer configurations, meeting specific needs in the realm of high-voltage electrical equipment.

Professional Transformer Vacuum Pump Unit Manufacturer-YUNENG

YUNENG can produce a variety of models, including 70L/S, 150L/S, 300L/S, 600L/S, and 1200L/S transformer drying vacuum pumps. Customized parts can also be provided according to the specific needs of customers. As a direct machine manufacturer, we can not only guarantee the production quality of our products but also offer competitive prices. We specialize in research, design, production, and customer service, which can provide the best service for customers from all over the world at any time.

In addition to the transformer vacuum pump, we can also provide various oil processing services. Including transformer oil, lubricating oil, turbine oil, hydraulic oil, etc., mainly for the production and sale of oil filtration and purification equipment.