SF6 Gas Recovery vs New Purchase: Cost, Emissions and Safety Comparison

Table of Contents

In high-voltage electrical equipment, such as gas-insulated switchgear (GIS), circuit breakers, and other power transmission hardware, SF6 is used as an insulating and arc-quenching gas. SF6 is an excellent gas for insulation and arc quenching due to its superb insulating properties and stability features. However, SF6 is also a potent greenhouse gas (GHG), with very high global warming potential (GWP), which has drawn increasing regulatory and environmental scrutiny worldwide.

Given both the critical role SF6 plays and its environmental risks, there is growing interest in the lifecycle of SF6 — especially the comparison between recovering and recycling existing SF6 versus purchasing new SF6 for equipment filling or maintenance. This article explores and compares these two approaches in three dimensions: economic cost, environmental impact (carbon footprint and emissions), and safety (leakage and contamination risk).

How is the SF6 Gas Lifecycle?

1. SF6 Production and Supply

When SF6 is needed, and we need to reorder more gas, it is common to obtain it from a manufacturer’s mass-produced high-pressure gas cylinders. Acquiring SF6 gas from a manufacturer requires a lot of energy. With SF6 gas, costs become high, and supply chains become more complex, especially with the need for high-pressure gas storage and transport tanks, which are also expensive. There are environmental impacts associated with production, purification, filling of gas in cylinders, and transport. All of these are affected simultaneously at the source.

Because SF6 demand is constrained by limited supply and increasing regulatory restrictions, the price of new SF6 tends to be high. As a result, repeated procurement — especially for large-scale operations or frequent maintenance — imposes high recurring costs.

2. SF6 Usage in Electrical Equipment

After you add SF6 to electrical appliances (GIS, breakers, etc.), it works really well as an insulator and becomes an arc extinguishing substance. From time to time, though, SF6 might leak (during installation, maintenance, handling, or due to imperfect seals) or it could, over a long time, become internally degraded (moisture, decomposition products) when devices lose their integrity or are taken apart. These leak points not only result in losing SF6’s abilities as an insulator, but also pose an environmental concern due to the fact that SF6, when released into the atmosphere, has a negative impact on global warming.

When equipment reaches end-of-life or needs servicing, the residual SF6 inside must either be vented (bad practice), disposed of, or — ideally — recovered and recycled using appropriate equipment.

3. End-of-Life: Recovery, Recycling and Disposal

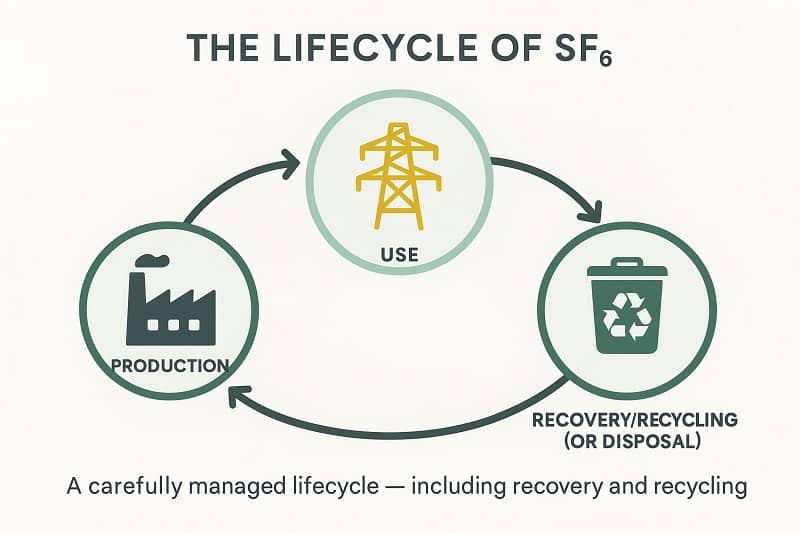

This is where SF6 gas recovery equipment and SF6 gas recycling come into the picture. Recovery equipment evacuates the gas from electrical equipment, then filters, purifies, and condenses it — often liquefying SF6 for storage in dedicated cylinders for future reuse. Proper recycling can return SF6 to a purity suitable for reuse in new or existing equipment, avoiding the need for new gas. If recovery and recycling are not viable, SF6 waste must be disposed or handled with strict controls to prevent atmospheric release.

Thus, the lifecycle of SF6 comprises production → use → recovery/recycling (or disposal). A carefully managed lifecycle — including recovery and recycling — can dramatically change the cost, environmental impact, and safety profile compared with a “use-and-discard / new-gas-only” approach.

Economic Analysis: Cost Comparison

One of the most direct benefits of SF6 recovery and recycling lies in cost savings. According to providers of recovery solutions, reusing recycled SF6 can reduce the need to purchase fresh cylinders — leading to long‑term savings that often offset the initial investment in recovery equipment.

- Reduced procurement costs: SF6 is an expensive industrial gas, and demand continues to rise while supply remains limited. Recycling existing SF6 means facilities need to buy far less new gas, reducing recurring procurement expenses by 30–50%, or even more in operations with high SF6 usage.

- Lower logistical and disposal costs: Without on-site recovery, used SF6 must be transported for disposal or sent to third-party recyclers, incurring cylinder transport costs, handling fees, insurance, labor, and regulatory compliance costs. Recycling on-site using recovery equipment eliminates much of these overheads.

- Investment Returns Over Time: No one should argue that effective liquefaction, filtration, and storage systems for recovery and recycling require a bit of capital up front. But from a cost perspective, after a few cycles of reuse, savings from purchased gases, disposal costs, and compliance fines often exceed the initial costs.

- Protect the Company from Regulatory Non-Compliance: As regulations regarding SF6 emissions become more and more stringent, failure to implement recovery systems exposes facilities to significant fines, operational infraction consequences, and reputational costs that should not be discounted. Recycling systems mitigate cost exposure, especially the hidden costs.

Because purely looking at economics, SF6 recovery and recycling is significantly more cost saving than business as usual, assuming new SF6 purchases, for companies that do regular maintenance, have large fleets of equipment, or have high SF6 usage.

Environmental Analysis: Carbon Footprint and Emission Reduction

Having a strong SF6 recycling plan will allow organisations to stay ahead of the game when it comes to greenhouse gas regulation because of the high global warming potential of SF6.

- Minimized greenhouse gas emissions: Recycling units have the potential to minimise greenhouse gas emissions over time. Recycling units avoid venting or releasing used SF6 to the atmosphere and reuse the purified gas. Modern recovery systems achieve high recovery rates that prevent SF6 waste.

- Minimized greenhouse gas emissions: In the life cycle of electrical equipment, new SF6 production emits greenhouse gases, and the synthesis of the gas is energy intensive. Demand for new gas is reduced when the life cycle of electrical equipment is completed, and thus the overall carbon footprint is decreased.

- Meeting international mandated emission reduction: The use of venting, SF6 disposal, and SF6 recovery is governed by international law that many countries have to comply with. The use of recovery and recycling equipment helps facilities meet these standards.

- Meets Corporate Environmental and Social Governance goals: Recycling facilities have responsible SF6 lifecycle management and thus meet their Corporate Social Responsibility goals, assisting overall Industrial Sustainability.

SF6 recycling is a VERY GOOD method to align SF6 for responsible recycling, logistics, with Global Climate goals.

Safety Analysis: Leakage and Pollution Risk

Considering cost and carbon footprinting involves addressing safety risks:

- Minimising leakage risks: Testing and using ultra-high quality closure systems results in no escape of SF6 gas into the atmosphere during maintenance and decommissioning.

- Ensuring gas purification: Used SF6 gas must be filtered and dried, removing moisture, oil residues, particles and their decomposition products, ensuring the used SF6 remains as effective and operational.

- Reducing toxic byproduct risks: The decomposition of SF6 during electrical arcing, i.e., inside aged and/or overloaded equipment, may produce toxic and corrosive byproduct gases such as sulfur fluorides. The contaminated gas stream must not be lost during recovery and purification, as performance degradation and various health and maintenance risks ensure unfit equipment.

- Meeting regulatory and operational compliance: In several jurisdictions, the uncontrolled venting or disposal of SF6 and byproducts during mineral processing and recovery is illegal. The operational use of recovery and recycling equipment demonstrates compliance with safety and environmental regulations, mitigating impacts regarding fines, operational delays, and damage to public reputation.

As such, the recycling of SF6 gas is, when done using effective recovery and recycling equipment, reducing health and safety risks and environmental impacts to the continued functioning of the high voltage electrical systems infrastructure.

Recommendations and Best Practices — Why Choose YUNENG SF6 Gas Recovery Equipment

In order to maximise the benefits of SF6 recycling and minimise risks, the following recommendations have been analysed and put into place:

Integration of SF6 recovery and recycling into existing programmes, having maintenance programmes, recovery of gases from retired equipment, and reuse of recycled SF6 for refilling or new installation.

- Use premium equipment conforming to the standard: For instance, YUNENG SF6 gas recovery/recycling equipment (QTHS series) is fully featured and includes vacuum recovery, gas purification (moisture, oil, dust), liquefaction of gas at a high pressure and safe (against evaporation) liquid storage.

- Mobility/ flexibility at the work site: YUNENG mobile recovery units, which are air-cooled and do not require external water sources, are well suited for on-site maintenance/field work and remote substations.

- Gas purity and recovery efficiency: SF6 that is recovered (not retained) from a unit with the appropriate equipment and is high enough in purity (suitable for reuse) will lower insulation risk and allow compliance with industry standards.

- Social, economic, environmental, and safety goals are to be optimised: effective recovery and recycling programmes reduce the gas procurement and disposal costs, lower greenhouse gas emissions, reduce the risk of contamination and leakage which is all positive for the operator and the environment, making for a truly positive outcome.

An accurate and dependable SF6 recycling and recovery system like the ones offered by YUNENG is a smart and future-oriented decision for any company that depends on SF6-insulated equipment.

Final Thoughts

When weighing the pros and cons of recovery and recycling SF6 gas along with the purchasing of new SF6 for economic, environmental, and safety comparison, the conclusion becomes clear that recycling is the most economically savvy option, provided all aspects of the process are completed with the right management, technique, and adherence to the policies surrounding the gas recovery process.

- From an economic point of view, recycling is the most economically advantageous as it removes the high costs associated with the purchase of new gas, the associated logistical costs, and the costs related to the disposal of the gas, and it is not uncommon for the recovery equipment to financially pay for itself.

- From an environmental point of view, recycling saves on the emissions of greenhouse gases as well as supporting the facility’s sustainable management of the remaining items in the facility’s life cycle, and this is pivotal as climate regulations and the related pressures from the UN on Environmental, Social Governance (ESG) are becoming more and more rigorous.

- From a safety and operational point of view, recovery and purification of the gas stream enhance performance, and the loss and contamination of the gas are reduced, adding many positive aspects; gas quality is preserved, and the equipment’s performance is increased, creating more reliability and longevity for the equipment.

Given these advantages, and especially where SF6 use is routine (maintenance, refilling, decommissioning), adopting SF6 recycling — for example, using YUNENG SF6 gas recovery equipment — should be the preferred strategy. This not only aligns with regulatory and environmental expectations but also makes sound economic and operational sense.