Cost Savings and Environmental Benefits of SF6 Gas Management

Sulfur hexafluoride (SF6) gas is critical for electrical equipment insulation in high-voltage applications. However, SF6 gas is also a potent greenhouse gas with a significant environmental impact. Thankfully, responsible SF6 gas management offers a win-win scenario: significant cost savings and environmental benefits.

Understanding SF6 Gas Management Options

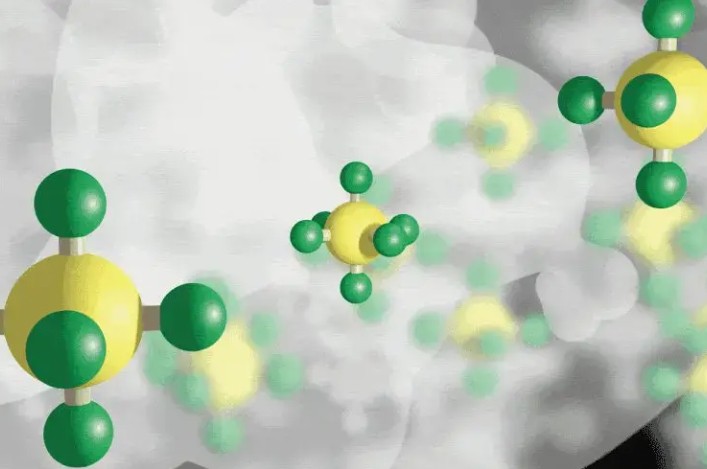

Sulfur hexafluoride (SF6) gas is an insulator with exceptional dielectric strength and arc quenching properties, making it ideal for high voltage electrical equipment like transformers and switchgear. However, the very property that makes it so effective – its high stability – also presents a challenge at the end of its useful life. SF6 gas has a staggeringly high Global Warming Potential (GWP), meaning it traps heat in the atmosphere for thousands of years at a rate significantly higher than CO2.

Disposing of SF6 gas responsibly is crucial to mitigating its environmental impact. Traditionally, there were limited options for SF6 gas management, and none were particularly ideal:

- Venting: The historical approach involved simply releasing the gas into the atmosphere. While convenient, this practice is no longer acceptable due to its severe environmental consequences. International regulations now strictly prohibit venting SF6 gas.

- Destruction: Specialized facilities can break down SF6 gas molecules into harmless byproducts. However, this process is expensive and doesn’t capture the potential of reusing the gas. Additionally, the destruction process itself can generate harmful emissions if not carefully managed.

Thankfully, a more sustainable and cost-effective option has emerged:

- Recycling: SF6 gas recycling facilities utilize advanced technology to remove impurities and moisture from used gas, purifying it to meet industry standards for reuse in electrical equipment. This option offers significant environmental and economic benefits, making it the preferred approach for responsible SF6 gas management.

Choosing the right SF6 gas management strategy depends on several factors, including the volume of used gas your operation generates, local regulations, and your budget. We’ll explore these factors and how they influence your decision-making process in a later section.

The High Costs of Traditional SF6 Gas Disposal

While traditional SF6 gas disposal methods might seem like a simple solution at first glance, they come with a hidden price tag that extends far beyond the immediate disposal fees. Here’s a deeper dive into why traditional disposal methods are not cost-effective:

- Facility Costs: Destruction facilities require specialized equipment and expertise to safely break down SF6 gas molecules. Maintaining and operating these facilities translates to high overhead costs, which are reflected in disposal fees.

- Logistics and Transportation: Depending on the location of used SF6 gas and the nearest destruction facility, significant transportation costs can be incurred. Coordinating logistics for safe transportation of SF6 gas adds another layer of complexity and expense.

- Hidden Fees: Disposal quotes may not always include all associated fees. Additional charges for pre-conditioning the gas, paperwork processing, and final disposal certificates can add up quickly.

- Lost Resource Value: Traditional destruction methods permanently eliminate the possibility of reusing the SF6 gas. This represents a lost economic opportunity, as virgin SF6 gas production incurs its own environmental costs.

In essence, traditional SF6 gas disposal is a one-way street with a hefty price tag. The high costs associated with destruction not only impact company budgets but also fail to capitalize on the potential of this valuable resource.

Here’s a cost comparison to consider:

- Traditional Destruction: Disposal fees can range from $20 to $100 per kilogram of SF6 gas, depending on factors like volume, location, and pre-conditioning requirements. Transportation costs can further inflate the total price.

- SF6 Gas Recycling: Recycling fees are typically significantly lower than destruction costs, often ranging from $2 to $10 per kilogram. Additionally, some regions offer rebates for companies that choose to recycle, further reducing the financial burden.

When considering the economic and environmental benefits, SF6 gas recycling emerges as the clear winner.

Environmental Benefits of Responsible SF6 Gas Management

SF6 gas poses a significant threat to our environment due to its high Global Warming Potential (GWP). While it offers valuable insulating properties in electrical equipment, even small leaks can have a substantial impact. Thankfully, responsible SF6 gas management offers a powerful tool to combat climate change:

- Reduced Greenhouse Gas Emissions: The primary environmental benefit of responsible SF6 gas management lies in its ability to significantly reduce greenhouse gas emissions. Recycling prevents the release of used SF6 gas into the atmosphere. Considering the high GWP of SF6, this translates to a dramatic reduction in its overall climate impact. According to the Environmental Protection Agency (EPA), one pound of recycled SF6 has the equivalent climate benefit of avoiding the emissions of 23 tons of CO2 over a 100-year period.

- Combating Climate Change: By mitigating SF6 emissions, responsible management directly contributes to the fight against climate change. Climate change is a complex issue, but every effort to reduce greenhouse gas emissions helps. SF6 gas management plays a vital role, especially considering its potency as a greenhouse gas.

- Resource Conservation and Sustainability: Responsible SF6 gas management promotes resource conservation and a more sustainable approach to electrical grid maintenance. Recycling allows for the reuse of a valuable resource, minimizing the need to extract and process virgin SF6 gas. This translates to a lower environmental footprint associated with SF6 gas production and usage.

- Compliance with Regulations: Many countries and regions have implemented regulations to limit SF6 gas emissions. Responsible management strategies, such as SF6 gas recycling, help companies comply with these regulations. This ensures that the electrical industry operates within a framework that prioritizes environmental protection.

- A Model for Responsible Industry Practices: By prioritizing responsible SF6 gas management, companies demonstrate their commitment to environmental stewardship. This sets a positive example for other industries and encourages the development of sustainable practices across the board.

In conclusion, the environmental benefits of responsible SF6 gas management are undeniable. By preventing emissions, promoting resource conservation, and fostering compliance with regulations, responsible management plays a crucial role in combating climate change and promoting a more sustainable future.

Choosing the Right SF6 Gas Management Strategy

Selecting the most effective SF6 gas management strategy requires careful consideration of several factors. Here’s a breakdown to help you make an informed decision:

1. Volume and Frequency of Use

- High Volume & Frequent Use: Companies with a large and consistent volume of used SF6 gas (e.g., utility companies, and electrical equipment manufacturers) are prime candidates for on-site recycling units. These units offer efficiency and convenience, allowing for immediate processing of used gas, minimizing storage requirements, and ensuring a quick turnaround time for reuse in operations. YUNENG offers portable and user-friendly on-site recycling devices that can be easily integrated into existing workflows.

- Low Volume & Infrequent Use: Companies with a smaller volume of used gas, or those who only generate SF6 waste occasionally, may find off-site recycling services more practical. Reputable SF6 gas management service providers can collect and transport used gas to centralized recycling facilities. This option eliminates the upfront investment of on-site equipment and the associated maintenance costs. However, it’s crucial to factor in potential transportation costs and longer turnaround times for gas return.

2. Regulatory Landscape

Understanding Local Regulations: Regulations regarding SF6 gas management can vary depending on your location. Researching and understanding local regulations is crucial to ensure compliance. Some regions might mandate specific gas recycling percentages or require certified providers for handling SF6 gas. YUNENG stays up-to-date on evolving regulations and ensures our services comply with all relevant standards, providing peace of mind for our clients.

3. Cost-Effectiveness: A Holistic View

- Total Cost Analysis: Consider the full cost picture, not just the immediate expense. Factor in the upfront cost of recycling equipment or service fees, but also consider potential rebates offered by your region, the ongoing cost of virgin gas purchases, and potential disposal fees associated with traditional methods.

- Long-Term ROI: While on-site recycling units might have a higher initial investment, they offer significant cost savings in the long run due to the elimination of transportation costs and reduced reliance on virgin gas purchases. Additionally, responsible SF6 management can help avoid potential fines for non-compliance with regulations.

4. Expertise and Support: Partnering for Success

Choosing a reputable SF6 gas management service provider with expertise in gas handling, transportation, and recycling is essential. Look for providers with a proven track record of safety, compliance, and customer service.

YUNENG offers comprehensive support throughout the SF6 gas management process, from initial consultation to gas recycling and even equipment maintenance (for on-site units). Our team of experts can help you navigate complex regulations, identify the most cost-effective solution, and ensure a smooth implementation process.

YUNENG SF6 Gas Management Device

As a leading manufacturer of SF6 Gas Recovery and Refilling Equipment, YUNENG understands the importance of choosing the right SF6 gas management strategy. Our commitment extends beyond simply offering equipment; we aim to be a partner in your sustainability journey.

YUNENG’s SF6 gas recycling devices are designed with versatility and user-friendliness in mind. Whether you require a portable unit for on-site operations or a larger solution for centralized processing facilities, we have a device to suit your needs. Our devices prioritize safety and efficiency, complying with industry standards and ensuring optimal gas processing.

For companies with a high volume of used SF6 gas, YUNENG’s on-site recycling units offer an attractive solution. These portable units can be seamlessly integrated into existing workflows, allowing for immediate processing of used gas. This minimizes storage requirements and ensures a quick turnaround time for reuse in your operations. Furthermore, YUNENG provides ongoing maintenance support for on-site equipment, ensuring optimal performance and longevity.