SF6 Gas Management: Standards and The Necessity of High-Purity Recovery

Table of Contents

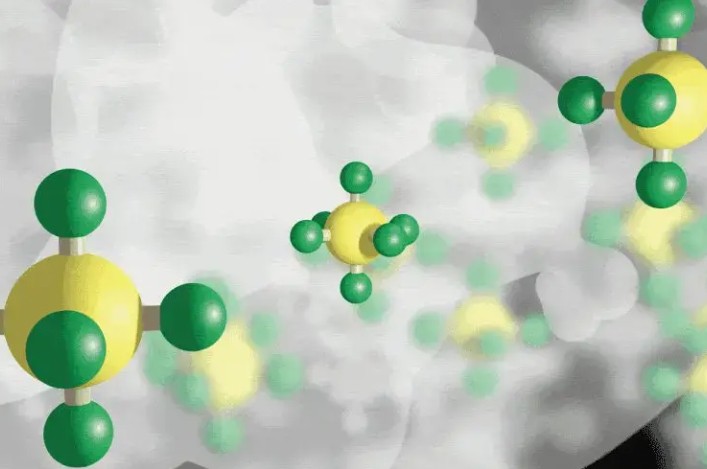

Sulfur hexafluoride ( SF6) is a key part of today’s power grid. It’s widely used as an insulator and to put out electrical arcs in high-voltage circuit breakers and gas-insulated switchgear (GIS). The thing is, it’s super reliable—thanks to its strong dielectric properties and thermal stability. But here’s the catch: it’s also the most powerful greenhouse gas we know of. Over 100 years, one ton of SF6 has the same warming effect as about 23,500 tons of CO2, and once it’s in the atmosphere, it can stick around for up to 3,200 years. This nature of the gas is both catastrophic toward climate change and essential, and therefore makes SF6 gas management, especially through recycling and recovery, an operational and environmental concern. This is the reason for focus and emphasis in the industry, and it is still heavily focused. These also focus on closed-loop handling systems and high reliability standards. Reusable SF6 must meet these critical gas standards.

Part 1: The Environmental and Operational Imperative for SF6 Gas Recovery

Three primary factors drive the motivation to recover and recycle SF6.

- Environmental Stewardship and Regulatory Compliance: The Kyoto Protocol, the EU F-Gas Regulation, and other international and local rules have put tight restrictions on SF6 emissions. When equipment is being maintained or taken out of service, if companies don’t properly recover and manage the gas, they could face big fines—and a lot of public backlash. On the plus side, recovering the gas means less of it ends up in the atmosphere, which actually helps fight climate change.

- Operational Efficiency and Resource Conservation: SF6 is a manufactured chemical and, hence, costly and valuable. There are other substantial cost savings in reselling the gas, and also savings in not purchasing new virgin gas, which helps in turning the supply chain secure for a gas that is critical for a utility. During the operation, 99.5 % of SF6 gas is also captured with the use of a high-efficiency recovery system.

- Safety: The arc quenching, breakdown products like HF, SO2 and other products, are extremely toxic and corrosive. Evacuation of such materials is done by specialized equipment. The rest of the personnel are protected due to the proper recovery techniques.

Part 2: Purity Standards for Re-using Recovered SF6 Gas

To make sure recycled SF6 still works right and won’t cause problems in high-voltage equipment, it’s got to be cleaned and tested carefully using international standards. The main one to follow is IEC 60480—it’s basically the go-to guide for checking SF6 taken out of electrical gear and figuring out whether it’s clean enough to reuse.

According to this standard, the recycled SF6 gas usually needs to meet or even exceed a few key purity levels before it can be safely put back into switchgear:

| Impurity Parameter | Maximum Allowable Content (Typical) | Operational Impact of Contamination |

| SF6 Purity (Volume %) | ≥97 % (Balance is Air/CF4 | Defines the maximum allowable concentration of non-SF6 gases. |

| Moisture Content (Dew Point) | ≤-36℃ | Water drastically reduces dielectric strength and, combined with breakdown products, causes corrosion. |

| Air / Nitrogen / CF4 | ≤3 %(Volume fraction) | Reduces the gas’s insulation performance and may affect operating pressure. |

| Decomposition Products (SO2 equiv.) | ≤50 ppmv (Volume parts per million) | Corrosive breakdown products like SO2 and HFdamage internal components. |

Hitting these tough standards means you need professional SF6 gas recovery and purification equipment—machines that can handle multi-stage filtering and pull a really strong vacuum.

Part 3: The Critical Importance of High-Purity Recycling

First, insulation needs to stay intact. Moisture is public enemy number one. Even tiny amounts of water vapor can seriously weaken SF6’s ability to insulate. If you put that wet gas back into equipment, you’re way more likely to get partial discharges or even flashovers—basically, electrical sparks where you don’t want them—which could lead to major failures.

Second, we’ve got to avoid corrosion. When SF6 finishes quenching the arc, it decomposes into unstable by-products. If there is moisture around, these fragments will react rapidly to form harmful corrosive acids, such as hydrofluoric acid (HF) and sulfur dioxide (SO2). What we are talking about here is not minor damage; These acids can actually corrode insulators, metal parts and seals, which means that expensive GIS equipment degrades more quickly. But when you clean the gas correctly, you can remove those dangerous pollutants and help protect your high-value system.

And third, it’s all about making equipment last longer. When utilities refill gear with recycled SF6 gas that meets or beats the original manufacturer’s specs, they’re ensuring everything works exactly as it should—both for insulation and for stopping arcs. That means the equipment keeps performing like new, and lasts way longer than if you were cutting corners with dirty gas.

Part 4: Recommended SF6 Gas Recycling Equipment (e.g., Yuneng)

Getting field-contaminated SF6 up to IEC purity standards isn’t simple—it takes serious, heavy-duty equipment. The SF6 recycling equipment is built like an all-in-one closed-loop systems that handle the whole job from start to finish.

Take the Yuneng QTHS Series SF6 Gas Recovery and Refilling Equipment—or other advanced models like it—as an example of what’s needed:

- High-efficiency recovery: These units use a powerful SF6 compressor and refrigerated liquefaction to pull gas out of equipment really well—even when pressure drops super low (like down to 0.05 MPa or less). The goal? To recover over 99.5% of the gas, so almost none escapes into the air.

- Multi-stage purification: This is where the real cleanup happens. Inside the machine, there are built-in filters and dryers—usually using things like molecular sieves and activated alumina—that take out three main types of junk:

- Particles: Dust and solid leftovers from electrical arcing inside the gear.

- Moisture: They dry the gas out way below the -36℃ dew point limit, which is critical.

- Breakdown by-products: Stuff like SO2 and HF—the nasty, corrosive gases formed during arcing—get trapped chemically before they can do damage.

- Vacuum and refill functions: Before putting clean gas back in, the unit pulls a deep vacuum on the equipment to get rid of any air or moisture. That way, when the purified SF6 goes in, the insulation stays strong and safe. Then, it refills the system exactly to the right pressure—no guesswork.

- Built-in storage: Once cleaned, the gas is stored safely in an internal or external tank. Often, it’s kept as a liquid because you can pack more into less space—all while meeting safety and pressure rules. These mobile, trolley-style units are a game-changer for field work. They let utility crews manage the entire SF6 lifecycle right on site—pull it out, clean it up, and put it back—safely, efficiently, and fully compliant with global environmental rules.

Conclusion

Recycling SF6 gas is no longer just a good idea, but something every responsible utility must do.With the harm this gas does to the planet, stringent regulations from around the world, and the need to protect expensive electrical equipment, there really is no way around it: we need SF6 gas recovery systems that are both efficient and deliver ultra-clean gas.By following standards such as IEC 60480 and using advanced equipment like the Yuneng QTHS series, power companies can do their part to reduce SF6 emissions while keeping their operations running smoothly – helping to move towards a cleaner, more reliable energy future.