Transformer Vacuum Pump Trends 2026: Intelligent Monitoring and Predictive Maintenance

Table of Contents

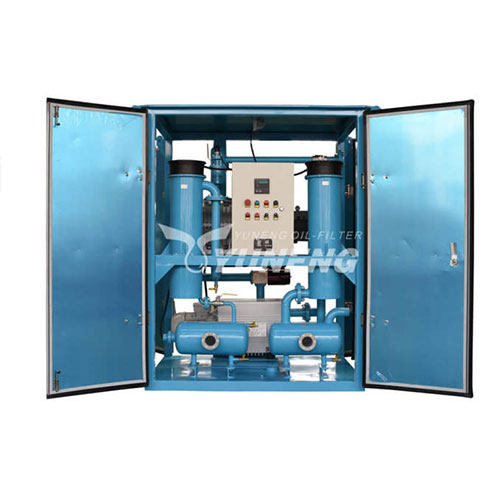

With the expansion of the power distribution networks, the maintenance of the critical equipment, such as transformers, has become more and more demanding as the networks are bigger, more complex, and more reliability focused. A vacuum pumping system is one of the most critical ones during transformer manufacturing, installation, commissioning, and on-site maintenance.

To begin with, a vacuum pump unit was predominantly seen just as a mechanical device that is responsible only for the creation of vacuum conditions during drying and oil filling. However, nowadays, that view is altered. The use of non-contact intelligent transformer vacuum pump systems, which are still important, is the most critical and general case of controlling the insulation quality, project schedule, operational safety, and overall life of the plant.

This paradigm shift has promoted the use of intelligent monitoring, process control, and condition-based maintenance platforms for the vacuum pumping systems in the power distribution and substation environments.

Traditional Transformer Vacuum Pump Maintenance Challenges

In order to see how beneficial intelligent systems can be, one must first ask what the limitations of the usual operation of vacuum pumps are.

1. Limited Visibility into Vacuum Performance

The majority of the time, it has to do with old-fashioned analog pressure meters and only some manual readings now and then. The quick changes in the vacuum level, the slower evacuation, or the internal leakage might not be noticed until the insulation quality is already weakened.

2. Reactive Maintenance and Unplanned Downtime

Generally, the maintenance of conventional vacuum pump units is done within fixed schedules or only when a fault occurs. The latter makes the following response more likely:

- Unexpected downtime during transformer installation

- Emergency repairs on site

- Increased risk of incomplete moisture removal

3. High Dependence on Operator Experience

It is mostly the experienced technicians who judge the vacuum system performance rather than some objective data. Operational personnel who leave or are responsible for more than one location continue to maintain consistency.

These challenges have pushed the industry toward intelligent vacuum pumping system solutions.

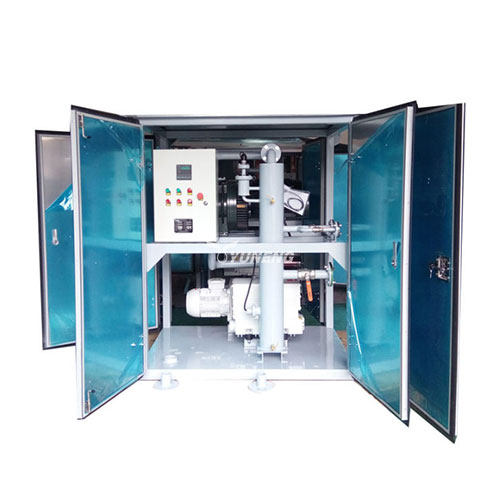

Core Technologies Behind Intelligent Vacuum Pumping Systems

Modern intelligent vacuum systems integrate mechanical reliability with digital intelligence. The following technologies form the foundation of smart transformer vacuum solutions.

1. Smart Sensors for Real-Time Data Collection

Advanced transformer vacuum pump systems are equipped with sensors that continuously monitor:

- Vacuum pressure and evacuation speed

- Oil vapor concentration

- Pump temperature and motor load

- Operating hours and duty cycles

This real-time data enables precise control and early fault detection.

2. PLC and Automated Control Architecture

The vacuum pumping system is enabled by a programmable logic controller (PLC) to:

- Automatically switch between rough vacuum and high vacuum stages, at the same time

- Coordinate multiple vacuum pump units (e.g., rotary vane pump + Roots pump)

- Optimize pump operation based on transformer size and moisture condition

The automation is helpful in minimizing errors during operation and, at the same time, making the process uniform.

3. Remote Monitoring and Digital Interfaces

Many intelligent systems now support:

- Touchscreen HMIs

- Remote monitoring via Ethernet or IoT platforms

- Centralized supervision of multiple vacuum pump units across substations

This is particularly valuable for utilities managing geographically distributed transformer assets.

Predictive Maintenance: A New Standard for Vacuum Pump Units

The transition from reactive to predictive maintenance brought by intelligent systems is one of the most influential benefits.

1. Data-Driven Maintenance Decisions

By analyzing operating trends, an intelligent vacuum pumping system can identify:

- Gradual loss of pumping efficiency

- Abnormal vacuum decay rates

- Increased motor load, indicating mechanical wear

- Maintenance can be scheduled before failure occurs.

2. Intelligent Alarms and Early Warnings

Instead of simple fault signals, modern systems provide graded warnings, such as:

- Pump oil degradation alerts

- Seal leakage indicators

- Excessive temperature rise notifications

This significantly reduces the risk of sudden transformer vacuum failure during critical operations.

Practical Benefits of Intelligent Transformer Vacuum Pumps in Field Applications

1. Improved Transformer Drying and Oil Filling Quality

The proper vacuum level and the ability to control it are the main factors for efficient removal of moisture and dissolved gases from the insulation of a transformer. Smart transformer vacuum pumping systems guarantee:

- Faster achievement of target vacuum levels

- Consistent vacuum stability during long drying cycles

- Reduced residual moisture in cellulose insulation

2. Shorter Installation and Commissioning Time

The total processing time is minimized as the evacuations are scheduled; thus, contractors find it easier to complete their jobs swiftly, and this is without any losses in quality.

3. Lower Long-Term Operating Costs

Although intelligent systems may have a higher initial cost, they reduce:

- Emergency repair expenses

- Pump oil consumption

- Premature component replacement

Over the lifecycle, smart vacuum pump units often deliver a lower total cost of ownership.

How Intelligent Vacuum Pumping Systems Influence Procurement Decisions

1. Key Selection Criteria for Modern Vacuum Pump Units

When evaluating a new vacuum pumping system, procurement teams increasingly focus on:

- Smart monitoring capability

- Compatibility with different transformer capacities

- Automation level and control flexibility

- Ease of integration with oil filtration and drying systems

2. Evaluating Vacuum Pumping System Supplier Capabilities Beyond Hardware

Suppliers of intelligent transformer vacuum pump solutions are now assessed on:

- Control software reliability

- Remote technical support capability

- System integration experience

- Long-term service and upgrade options

This reflects a broader shift from equipment purchasing to solution-oriented procurement.

Integration of Vacuum Pumping Systems with Transformer Oil Purification Equipment

Intelligent vacuum pumps are frequently integrated with transformer oil purification machines. This synergy allows:

- Coordinated control of vacuum dehydration and degassing

- Automatic adjustment based on oil condition

- Higher efficiency in removing moisture and dissolved gases

Such integrated systems are becoming standard in modern power distribution maintenance strategies.

Future Trends in Intelligent Vacuum Pumping Systems

1. Digitalization and AI-Assisted Optimization

Future vacuum pumping systems are expected to use AI algorithms to:

- Optimize evacuation curves

- Automatically adapt to different transformer insulation conditions

- Predict maintenance needs with higher accuracy

2. Modular and Scalable Vacuum Pump Units

Users will be able to adjust capacity through the use of project-based vacuum pump unit addition or removal, thanks to the standardized and modular designs.

3. Energy-Efficient and Environmentally Friendly Designs

Manufacturers are increasingly focusing on:

- Lower energy consumption

- Improved oil mist recovery

- Reduced environmental impact

These features align with global sustainability goals in the power industry.

Frequently Asked Questions (FAQ)

Q1: Are intelligent vacuum pumping systems only suitable for large power transformers?

No. Intelligent vacuum pumping systems are increasingly used for medium and small transformers, especially where high insulation quality and process consistency are required.

Q2: Does smart monitoring increase maintenance complexity?

On the contrary, intelligent monitoring simplifies maintenance by providing clear diagnostics and predictive alerts, reducing reliance on manual inspection.

Q3: Can existing vacuum pump units be upgraded to intelligent systems?

In many cases, yes. Sensors, PLCs, and monitoring modules can be retrofitted, depending on the original vacuum pump unit design and compatibility.

Q4: Do intelligent transformer vacuum pumps require highly skilled operators?

Most systems feature user-friendly interfaces and automated controls, lowering the skill threshold for daily operation.

Q5: Is the investment in intelligent vacuum pumping systems economically justified?

Yes. Reduced downtime, improved transformer reliability, and lower lifecycle costs often outweigh the initial investment within a few years.